- Science

Targeted Printing

Single-cell technology

Bright prospects for personalized medicine: Experts from the Fraunhofer Institute for Microengineering and Microsystems IMM harness their know-how in microfluidics and single-cell technologies to print organ structures.

Single-cell technologies play a key role in studying and characterizing cells. Dr. Christian Freese, Head of Infection and Cancer Diagnostics at Fraunhofer IMM, and his colleagues use microfluidics to dispense and study single cells on a targeted basis. In their liquid biopsy diagnostic platform, they detect and dispense circulating tumor cells (CTCs) and other biomarkers from liquid biopsies for accessible and comprehensive diagnostics. But the researchers wanted to take things one step farther: Why not build something with the individual cells?

The Fraunhofer IMM TrapJet principle

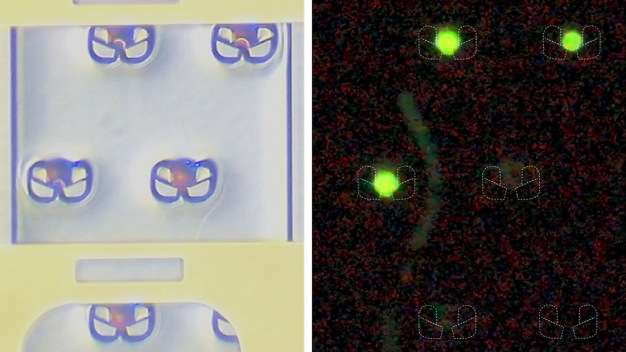

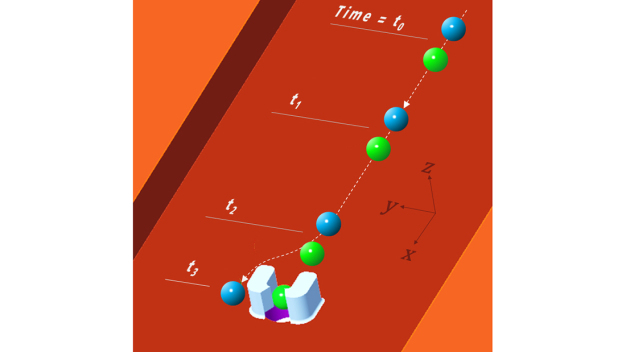

With the goal of putting their developments and methods to work for printing cells, they realized special microfluidic structures on silicon-based wafers in the cleanroom at their institute. These structures are designed to “trap” cells. The specialists introduce human cells into ultra-fine channels on microfluidic chips, and the cells are captured by special structures there as they flow. The specific geometry of these structures ensures that only individual cells are trapped, while others flow onward to the next unoccupied trap. There are many traps lined up one after another in a single channel, so the experts can zero in and release cells simultaneously in different places and then reuse the traps.

Much like in an inkjet printer, a heat bubble dispenses the cell from the nozzle and deposits it inside a tiny drop of liquid. Different cell types are given separate print heads and printed in parallel, each running through their own microfluidic channels.

“We use microfluidics to cover all of the parameters that successful bioprinting requires: We print cells on demand, in a fast, sterile process. At the same time, this method ensures that the viability rate for the printed cells is high. Another part of this is that we use the characteristic bio-inks composed of the cell and a liquid specific to the cell type, which can also be handled in microfluidics,” Freese explains.

Many existing methods only generate a thin line of bio-inks containing cells distributed at random. The Fraunhofer specialists print ultra-tiny droplets not much larger than the cell itself. This allows them to achieve superior resolution: Each cell is positioned precisely and can interact directly with neighboring cells. The researchers plan to use this method to build organ cultures, for example, which industry could use to test medications. The Fraunhofer experts’ stated aim is to print tissue for skin transplants or entire organs.

More microfluidics for medicine

To tap into the tremendous potential of these methods in medicine, the experts from Fraunhofer IMM will be teaming up next year with their colleagues from the Clinical Health Technologies department at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Mannheim to launch a high-performance center for single-cell technologies, where they will pool and advance their expertise.

The experts were attending the MEDICA 2024 trade show, where they presented their solutions at the joint Fraunhofer booth. In addition to single-cell printing, attendees were able to play a specially developed VR game to try their hand at marking and later isolating rare cells.

Fraunhofer-Institut für Mikrotechnik und Mikrosysteme IMM

55129 Mainz

Germany