- Training, Schulung

Produktion von Lebensmitteln in einer reinen Umgebung als Grundsäule für die Verlängerung der Haltbarkeit

Verbraucher stellen wachsende Anforderungen an Lebensmittel, die viele Unternehmen vor immer neue Herausforderungen stellen. Die Ziele sind umfangreich und anspruchsvoll. Von der Sensorik, über Clean Labelling bis hin zur möglichst langen Haltbarkeit unter wenig anspruchsvollen Lagerbedingungen. Die Forderungen nach natürlichen und möglichst gering verarbeiteten Lebensmitteln stehen dabei nicht selten im Widerspruch zu dem, was technisch machbar ist.

Die Frage nach der Haltbarmachung von Lebensmitteln beschäftigt die Menschheit schon lange. Konservierte man anfangs noch durch Trocknen, Erhitzen und Einlegen, greifen die Menschen heutzutage auf Erfindungen wie den Kühlschrank oder den Autoklav zurück. Aus diesen technischen Meilensteinen erwuchs eine Reihe an weiteren Lösungsmöglichkeiten für das ureigenste Problem. Allen Methoden liegt jedoch der gleiche Gedanke zugrunde: Wie verlangsamt man das Wachstum und die Vermehrung von Mikroorganismen im Lebensmittel?

Grundsätzlich existieren drei Strategien für die Haltbarmachung von Lebensmitteln. Im Wesentlichen stehen chemische, physikalische und biologische Konservierungsverfahren zur Verfügung. Konkrete Beispiele lauten wie folgt:

Viele Konservierungsmethoden – vollumfänglich im Einzelnen angewandt – verändern die Lebensmittel so weit, dass sensorische Eigenschaften wie Aussehen, Geruch, Geschmack, Textur und/oder Konsistenz ebenso stark verändert werden. Die ursprüngliche Frische und Sensorik gehen teilweise oder sogar vollständig verloren. Das wollen Verbraucher heutzutage oftmals nicht hinnehmen.

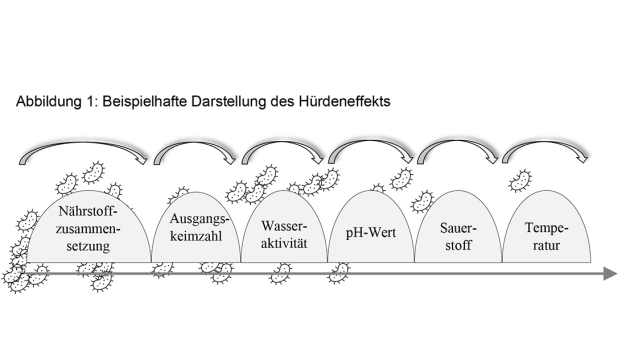

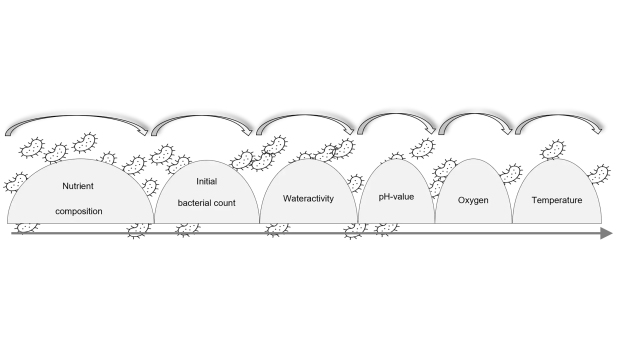

Daher liegt die Idee nahe, verschiedene Verfahren zu kombinieren, um einen Kombinationseffekt zu erzeugen. In der Praxis kombinieren Hersteller gezielt zwei oder mehr Konservierungsverfahren in festgelegter, logistischer Vernetzung. Diese Verfahren können, im Sinne einer mikrobiologischen Reduzierung von Keimzahlen und Stabilisierung der Lebensmittel auch als Hürden bezeichnet werden. Man spricht vom sogenannten Hürdeneffekt. In Abbildung 1 sind beispielhaft einige marktübliche Hürden dargestellt. Die Abbildung verdeutlicht, dass Mikroorganismen zwar eine quantitative Reduzierung erfahren, jedoch schlussendlich alle Hürden „überspringen“ können.

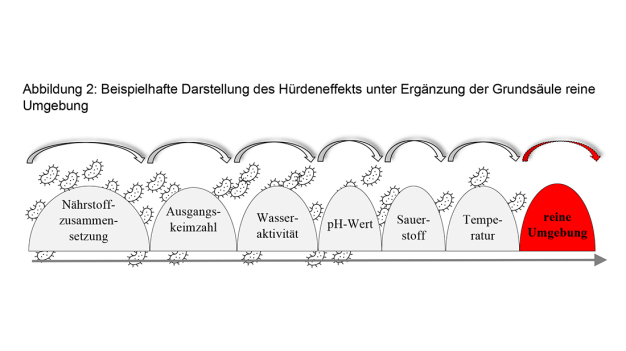

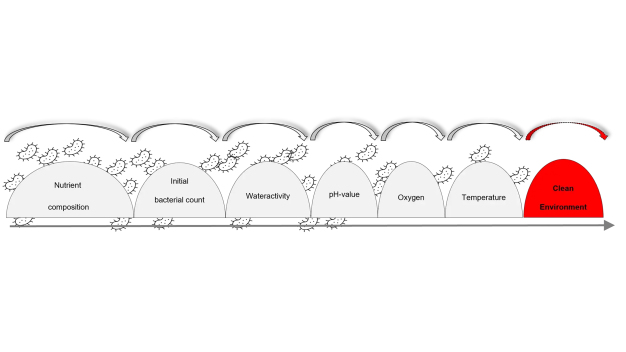

Die wenigsten der dargestellten Konservierungsverfahren erreichen eine vollständige Abtötung aller Mikroorganismen. Das ist ein Problem, denn bereits das Überleben eines einzigen Mikroorganismus kann schlussendlich zum Verderb führen. Vermehrt sich dieser eine Mikroorganismus, so kann innerhalb eines bestimmten Zeitrahmens wieder eine exponentielle Vermehrung und damit Verderb einsetzen. Viel interessanter ist daher die Betrachtung einer weiteren Lösung: Die Herstellung von Lebensmitteln unter möglichst reinen Bedingungen, d. h. in einem Reinraum. Diese Grundsäule für die Verlängerung der Haltbarkeit von Lebensmitteln wird nachfolgend detailliert betrachtet.

Eine im Beispiel aufgeführte Hürde ist die Ausgangskeimzahl. Je geringer diese ist, desto länger wird der Verderb eines Lebensmittels hinausgezögert. Hierbei muss der mikrobiologische Status aller Zutaten betrachtet werden, wenn nach dem Zusammenfügen des Lebensmittels kein Konservierungsverfahren am oder im Endprodukt vorgesehen oder möglich ist. Hier würde wahrscheinlich ein mikrobiologischer Summeneffekt eintreten, d. h. die Ausgangskeimzahlen jeder einzelnen Zutat fließen schlussendlich im Endprodukt zusammen, sodass hier sehr viele verschiedene Mikroorganismen in großer Menge zu finden wären. Diese beschleunigen unter Umständen in ihrer Gesamtheit den Verderb und verkürzen die Haltbarkeit.

An dieser Stelle kann die Herstellumgebung einen bedeuteten Beitrag leisten, um die Gesamtkeimzahl im Endprodukt möglichst niedrig zu halten. Denn je reiner bzw. keimarmer die Herstellumgebung ist, desto weniger Mikroorganismen aus dieser gelangen in das Endprodukt. Somit wären bei einer mikrobiologischen Bewertung lediglich die Ausgangskeimzahlen der einzelnen Zutaten in der Risikobewertung zu berücksichtigen.

Abbildung 2 zeigt den zuvor beschriebenen Hürdeneffekt unter Ergänzung der reinen Umgebung, als eine zusätzliche Schutzmaßnahme im Herstellungsprozess von Lebensmitteln.

Einige Hersteller haben sich bereits mit der Produktion unter reinen Bedingungen einen Marktvorteil geschaffen. Dies ermöglicht es ihnen der Verbrauchererwartung nach Frische und möglichst gering verarbeiteten Lebensmitteln in Verbindung mit längerer Haltbarkeit gerecht zu werden.

In diesem Zusammenhang spielt die Reinigung der Produktionsumgebung und der Maschinen eine immanente Rolle, die in der Praxis häufig unterschätzt wird. Nur durch regelmäßige Reinigung und Desinfektion kann der Status der reinen Umgebung hergestellt bzw. aufrechterhalten werden. Unstrittig ist hier die Verwendung geeigneter, zugelassener Reinigungs- und Desinfektionsmittel in Verbindung mit ebenso geeignetem Reinigungsequipment und einer systematischen Reinigungstechnik in definierten Intervallen. An dieser Stelle sei auf die gesetzliche Verpflichtung zur Dokumentation aller durchgeführten Arbeiten entsprechend vorgegebener Anweisungen hingewiesen.

Eine Produktion unter möglichst reinen Bedingungen aufzubauen, diese täglich zu leben und aufrechtzuerhalten kann eine Herausforderung darstellen. Hier bietet die Reinraum Akademie kundenspezifische Coachings und Schulungen an. Informieren Sie sich bei Tagestrainings in Dreieich, Leipzig oder Marburg beispielsweise zu den Themen Verhalten und Hygiene im Reinraum oder professionelle Reinraumreinigung. Diese Trainings informieren nicht nur über die Herkunft, Verbreitung und Auswirkungen von verschiedenen Kontaminationen in der reinen Umgebung: Unsere Absolventen erhalten umfangreiche Informationen, Kontamination zu kontrollieren und zu minimieren. Sie erhalten die Gelegenheit, verschiedene Materialien/Ausrüstungsgegenstände vor Ort zu testen und Methoden anzuwenden.

Alternativ lassen Sie sich von einem unserer Experten direkt in Ihrer Produktion die Fallstricke und Besonderheiten Ihres reinen Bereichs aufzeigen, um der Betriebsblindheit den Garaus zu machen. Tipps und Tricks gibt es dabei inklusive. Um Ihre Mitarbeitenden detailliert und entsprechend der unternehmensinternen Gegebenheiten zu schulen, kommen wir zu Ihnen und

– erstellen ein maßgeschneidertes Schulungskonzept

– analysieren Ihre Prozesse

– erarbeiten gemeinsam mit Ihnen mögliche Lösungen für Ihre Probleme und Schwachstellen und

– optimieren Reinraum, Prozesse und Mitarbeitende

![]()

CWS Cleanrooms Deutschland GmbH & Co.KG

Dreieich Plaza 1 A

63303 Dreieich

Deutschland

Telefon: +49 6103 3091290

Telefax: +49 6103 309169

eMail: cleanrooms.de@cws.com

Internet: http://www.cws.com/reinraum