New company headquarters: medical silicone component manufacturer constructs 1,900 m² clean room and adds extrusion processes to the company portfolio

Manufacture of medical devices

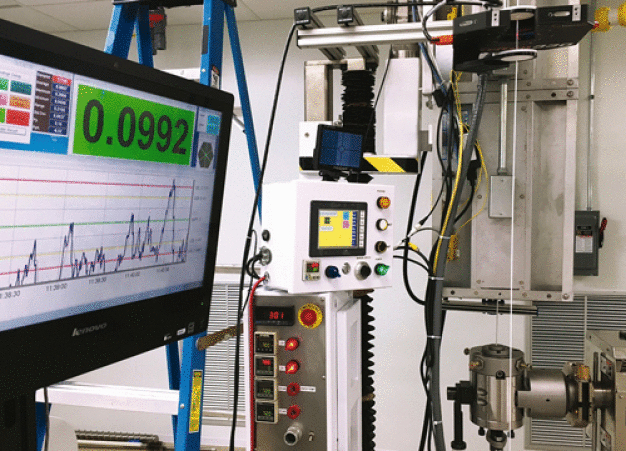

Thanks to its biocompatibility, silicone rubber is more and more frequently used in medical implants, such as defibrillators, heart pumps or components for reconstructive surgery. As these implants must not contain any contaminations which could endanger the health of patients, some extremely stringent requirements are in place concerning the minimized particle content of these products. In order to satisfy these requirements and to respond to the increasing demand for components with high standards of cleanliness, the company FMI, a specialist in complex silicone parts based in Chicago, has constructed Class 7 clean-room production facilities with a surface area of 1,900 m² at new premises. At the new company headquarters, state-of-the-art extrusion processes will be applied to manufacture silicone tubing for medical devices.

“Silicone rubber is suitable for medical devices thanks to its electrical insulation properties, its flexibility and durability as well as its high thermal resistance, among other things,” Werner Karau, European Commercial Leader at Flexan, explains. Compliance with the required cleanliness standards is critical in the manufacture of the components, in many cases requiring production in a clean room: generally, a Class 7 clean room is required for parts used to build Class 2 and 3 medical devices. To date, FMI Chicago has manufactured various silicone components for Class 2 short-term implants, single-use products and Class 3 long-term implants in clean rooms with a surface area of about 850 m² in total.

To meet the challenges of the market and to increase its own production capacity, the subsidiary of U.S. contract manufacturer Flexan has decided to use additional facilities for clean-room production. Hence the company moved into new 6,500 m² headquarters close to the former production site in Chicago and constructed an ISO Class 7 clean room with a surface area of approx. 1,900 m² there. Consequently, FMI can now produce four times the components for Class 2 and 3 medical devices. “As it is our intention to add extrusion to our portfolio, these new facilities were initially equipped with three production lines,” Karau reports. The extruders feature a proprietary design which not only facilitates access to the silicone feed section, but also makes cleaning and adjusting the scraper blades easier. “We can use these installations for highly diverse processes, e.g. micro-lumen or multi-layer extrusion,” Karau explains. “This ensures FMI’s manufacturing capacities are extremely flexible.” Initially, the focus is on various catheter products as well as other medical devices combined with a tube, which are also assembled with other components at MEDRON’s own factories.

Flexan, LLC

IL 60069 Lincolnshire

United States