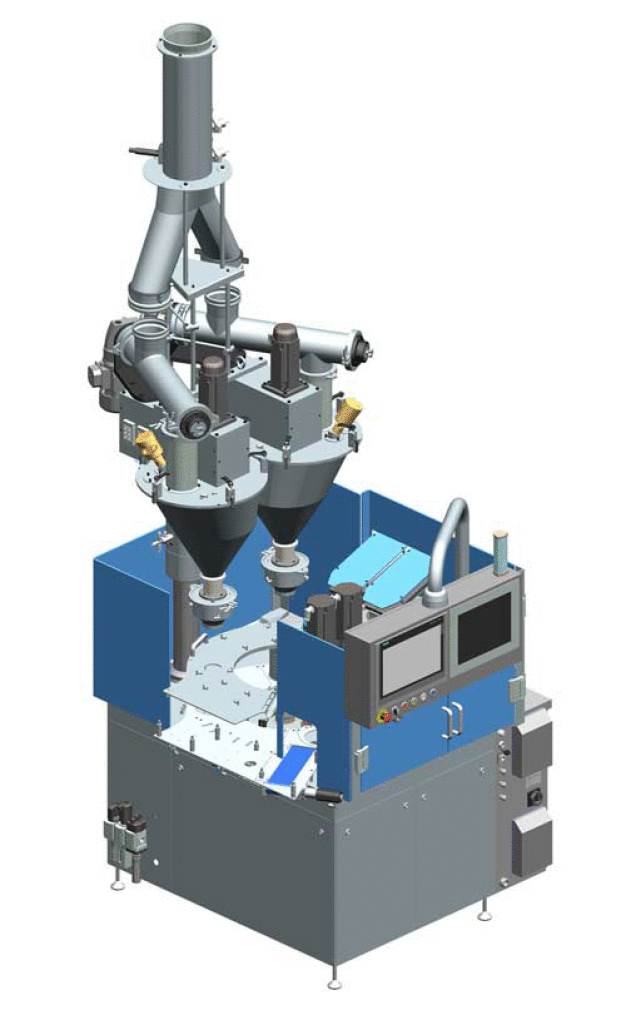

Optimized Can Filling and Seaming Machine

As specialist in building individual machines and complete lines to fill and close cans and jars with powder or dry products Swiss Can Machinery AG (SCM), Berneck/St. Gallen, presented itself on the trade fair Interpack. The company has a leading market position concerning can filling and seaming machines that work under modified atmosphere.

With the help of the innovative gassing systems V-Matic including evacuating and G-Matic cans with less than 0.5 respectively 2 per cent residual oxygen can be manufactured. Moreover the facilities fulfill high hygienic standards and possess all necessary certificates. By replacing mechanical aggregates with electrical ones, cleaning and changeover times are considerably minimized.

At this year´s Interpack, SCM showed a further developped model of type G-Matic 127. New technical features of this can filling and seaming machine are more precisely operating level indicators and a simplified gassing control by self-calibration. Also integrated are Oxymats by Siemens for permanent supervision of residual oxygen, eventually causing a production stop. Another novelty: all steel components now are made of best V4A- respectively AISI 316 quality.

The other production program of Swiss Can Machinery AG includes semi-automatic can seaming machines, empty can cleaning and disinfection machines and cappers including lid destacker, for example. Moreover, conveyors and additional transport equipment are offered. The most important customer group are producers of baby food, especially manufacturers of milk powder. Other clients come out of the coffee, sweets, snacks and pharmaceutical industries. Beside Europe the Asian area is a constantly growing market for the extremely export-oriented company.

Swiss Can Machinery AG

9434 Au

Switzerland