- Trade fair

Sustainable processing and packaging technologies all from one source

Romaco at PACK EXPO International 2024

This year’s PACK EXPO International in Chicago (USA) will be an opportunity for the Romaco Group to showcase its technologies for compressing and coating tablets as well as for the secondary packaging of ophthalmic products. All machines from this one stop solutions supplier are developed and manufactured in accordance with the Group’s high sustainability standards.

Romaco’s portfolio covers the entire process chain for manufacturing and packaging pharmaceuticals, nutraceuticals, food, cosmetics and chemical products. Whether as stand-alone machines or integrated lines, the one stop supplier’s solutions can be flexibly configured and are also extremely versatile. Romaco’s technologies score with excellent overall equipment effectiveness (OEE) based on top quality and performance as well as optimized retooling and cleaning times.

Sustainable system design is a key development priority with all of the manufacturer’s products. True to the principle of “avoidance is better than reduction is better than compensation”, Romaco has significantly improved its machines’ carbon footprint. Earlier this year, the company earned a silver medal in the EcoVadis Sustainability Rating for its commitment to climate protection.

Romaco will take advantage of the upcoming trade fair to show the KTP 1X compaction simulator from Romaco Kilian, the TPR 25 Pilot tablet coater from Romaco Tecpharm and the PC 4400 high speed continuous motion cartoner from Romaco Promatic.

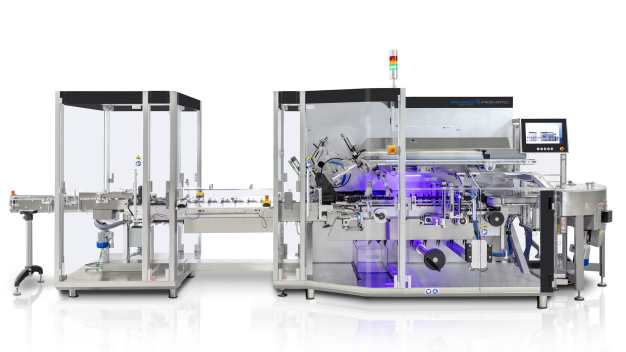

PC 4400 continuous motion cartoner from Romaco Promatic with ophthalmic bottles feeding

The PC 4400 high speed continuous motion cartoner from Romaco Promatic is designed for processing a very wide range of products. With its safe product handling concept, the cartoner is perfect for packaging extra-lightweight plastic bottles with small diameters and low filling volumes, such as those used for ophthalmics. A double conical wheel infeed system ensures safe transfer of the bottles to the cartoner, even at the machine’s maximum speed. The cartoner can also be configured for feeding ecotrays with vials placed upright. Depending on the requirements, glass vials, tubes, strips, blisters and countless other products can likewise be packaged quickly and reliably. The Promatic PC 4400 achieves a maximum output of 400 cartons per minute. Its positive carton opening system means that there is no friction whatsoever, paving the way for gentle handling, especially where recycled cardboard is concerned. The GMP-compliant balcony design and ergonomic working height moreover speed up safe line clearance. The cartoner’s buckets are produced by 3D printing so that material consumption during the manufacturing process is radically curtailed. Numerous anodized aluminum components and the recycled acrylic glass housing further reduce the cartoner’s carbon footprint. If required, Romaco Promatic’s PC 4400 can be flexibly integrated into the diverse packaging concepts of the pharmaceutical, nutraceutical, cosmetics, food and chemical industries.

TPR 25 Pilot mobile tablet coater from Romaco Tecpharm for batch sizes from 5 to 100 percent

The TPR 25 Pilot mobile tablet coater is an extremely compact pilot-scale unit for simple plug & play commissioning. For this purpose, all inlet and exhaust airflow systems required for the coating process have been integrated into the machine. As a modern all-in-one solution, its applications cover everything from development activities and scale-ups to the production of very small batches. The pilot coater is designed to handle batches weighing anything from 1 to 25 kg, making it suited for an extremely wide batch size range from 5 to 100 percent. The coating pan’s enormous flexibility is made possible by fully automated processes requiring no manual adjustments. The TPR 25 Pilot is equipped with a patented spray arm, which is controlled by a sonar system that automatically adjusts the distance between the spray gun and the tablet bed. Thanks to the spray arm’s intelligence, the coater does not have to be stopped and opened to correct the spray distance while the process is running. In addition to this, the extendable spray arm has movable nozzles to ensure the ideal spray angle in any situation. The process air flowing through the tablet bed follows a precisely controlled path, which can be automatically adapted to the filling level in the drum with the aid of an exhaust flap that opens steplessly. This results in remarkably accurate application of the coating suspension and ultra-efficient drying of the tablet bed. From a sustainability viewpoint, Romaco Tecpharm’s TPR 25 Pilot consequently impresses with significantly shorter processing times coupled with lower energy and spray liquid consumption.

Romaco Kilian KTP 1X compaction simulator for digital tablet development

The KTP 1X is Romaco Kilian’s smart compaction simulator for tablet development using digital tools. This all-in-one instrument was designed for research and development activities, but also allows targeted troubleshooting and process optimization in addition to upscaling. The single-stroke press is capable of simulating any standard rotary press, making it much easier to conduct technology transfer and scale-up trials, among other things. The versatile measurement system is perfect for designing and analyzing mono-layer, bi-layer and triple-layer tablets as well as tab-in-tab formats. The KTP 1X determines the ideal compression force/hardness profile for any tablet design, taking account of the various ingredients and parameters. Its compression studies are highly automated, and so only a few test series are needed to obtain meaningful results when characterizing a formulation. This high measuring accuracy goes hand in hand with extremely low product consumption – a significant factor when it comes to economy and sustainability. A special data module gives users worldwide secured access to raw measurement data at any time, even when the press is not in operation. Decentralized data analysis and processing has numerous advantages, enabling research projects to be implemented more efficiently. Thanks to its very small compaction area, this space-saving instrument fits conveniently into any laboratory as well as being quick and easy to clean. Depending on the model, Romaco Kilian’s KTP 1X achieves compression forces of up to 80 kN with a maximum output of 1800 tablets per hour.

Romaco Group

76227 Karlsruhe

Germany