- Trade fair

Super-precise core pulling units with µm accuracy

Servomold at the Fakuma 2024:

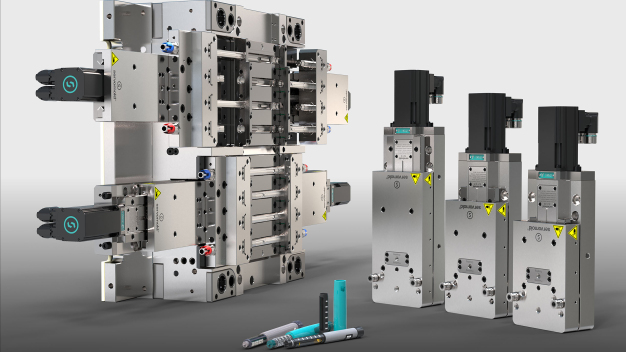

At Fakuma 2024, Servomold, a leading specialist in the automation of injection mold tools, will be presenting at stand A2-2111 in hall A2 a new generation of servo-electric core-pulling units of the SLY type, equipped with ball screw drives, which position slides and cores with µm accuracy. To ensure this standard-setting accuracy, their carriage contains precision bores with special fine centering elements for the assembly of universal slides. Another special feature is the linear guides integrated into the units instead of high-maintenance slide guides inside the mold frame. This relocation to the outside enables particularly compact mold dimensions and reduces maintenance costs.

Typical applications for the cleanroom-compatible linear motion systems are sleeve-shaped parts with the highest quality requirements, for example housings and cartridge holders for medical technology systems such as auto-injectors. All versions are suitable for mounting on both new and existing molds. This means that the latter can be electrified efficiently and in a resource-saving manner as part of a retrofit.

The stroke of the new SLY-S-150 core pull unit is 150 mm, 100 mm for the SLY-S-100 and 75 mm for the SLY-S-075. All versions deliver 6 kN thrust as standard. If required, an optional, easily retrofittable planetary gear box doubles this value to 12 kN. The option of mounting different slider bodies on the carriage ensures application-specific flexibility. Other special features include the ability to perform multi-stage movements in order to customize the demolding process, as well as optional motor brakes that hold the system in position in the event of power failures.

Like the servo-electric linear actuators of types SLA and SSA from Servomold, presented at last year's Fakuma, the new units are compact, powerful and clean alternatives to hydraulic and pneumatic cylinders, which are traditionally used to perform translational slide, core or plate movements in injection mold tools. All actuators are controlled via the Servo MoldControl (SMC), which has been available on the market since 2024, with its intuitive touch panel and automatic switching between different encoder systems. Depending on the configuration, the system can control up to eight servo drives.

Thomas Meister, Managing Partner of Servomold, comments: "With the servo-electric drive of the SLY core pulling units and the minimal lubrication of guides and spindles, we fulfil customer requirements that include not only precision and high dynamics but also suitability for use in cleanrooms. On this basis, we are planning to significantly expand our business in the growing market for medical technology devices in the near future."

In addition to the new SLY core pulling units, Servomold will also be presenting its options for developing application-specific solutions and its entire portfolio of cost-efficient, standardized servo system components at Fakuma 2024. In addition to servo-electric single to fourfold unscrewing units and worm unscrewing units for unscrewing threads, this also includes ready-to-use, complete unscrewing halves, powerful servo drive units and linear actuators, space-saving, integrable indexing plate drives, threaded core sets and rotary cooling systems for unscrewing units.

Servomold GmbH & Co. KG

64711 Erbach

Germany