- Trade fair

motan to showcase cutting-edge solutions for efficiency and sustainability at FAKUMA 2024

From October 15 to 19, 2024, FAKUMA will bring together exhibitors from around the world to address the pressing challenges of efficiency, resource conservation, and sustainability. motan, a leader in materials management, will be at Hall B1, Stand 1111, presenting exciting new additions to its portfolio of reliable and precise gain-in-weight dosing and mixing units, particularly for the medical and pharmaceutical sectors. Additionally, the motan Group will highlight its swift brand, known for combining high quality with exceptional price-performance ratios.

Driving efficiency and sustainability

motan has long been committed to optimizing efficiency across its products and processes, focusing on material flow and sustainability. At this year's FAKUMA, efficiency takes center stage, encompassing not only materials and energy but also the operation of production facilities and entire production processes. Achieving seamless production requires a holistic approach where every step is meticulously interlinked, using sustainable materials and energy-saving products. Efficiency at all levels is the key to unlocking a company's highest and most sustainable potential.

Advanced dosing and mixing solutions: Flexible and reliable dosing, also FDA-compliant

The GRAVICOLOR 310 and 610 gravimetric dosing and mixing units feature motan's unique cone dosing system, allowing precise mixing of up to eight materials with recipe accuracy. Their modular design ensures optimal performance, flexibility, and reliability in injection moulding, blow moulding, and especially extrusion applications.

For the medical and pharmaceutical industries, motan introduces the GRAVICOLOR 110 med. This FDA-compliant unit, designed for injection moulding, blow moulding, and extrusion, utilizes vertical slide technology for precise mixing of up to four materials, ensuring maximum recipe accuracy.

All GRAVICOLOR units are equipped with the enhanced IntelliBlend analysis function, which records and documents recipes, materials, and operating environments. This self-optimizing system ensures users achieve the best possible working point continuously.

swift brand: High quality, cost-effective solutions

The motan Group’s swift brand will showcase several standout products, emphasizing simplicity and efficiency:

– sDRY 250 dry air generator: It offers energy efficient drying with excellent dewpoints and many advanced features as standard.

– sCOMPACT dry air dryer: Available in various sizes, perfect for single or twin processing machine applications. The flexible dryer with integrated conveying and the option of controlling a dosing & mixing unit via its full colour touch display.

– sCONVEY HOS material loaders: Cost-effective and efficient conveying process automation.

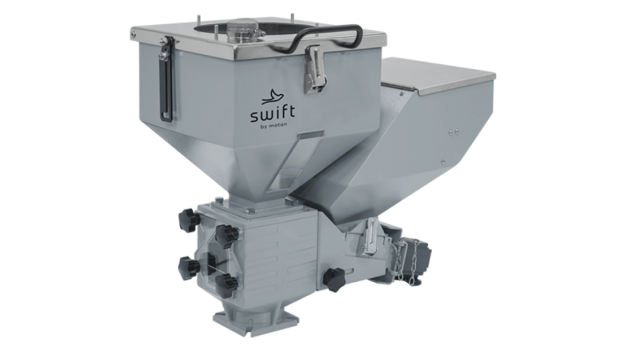

– sCOLOR V additive dosing & mixing unit: Ideal for masterbatch and regrind dosing applications, offering quick delivery and cost-effective performance.

Promoting holistic process understanding

Process efficiency is rooted in the effective operation of production systems. Through the motan academy, users can receive comprehensive training that extends beyond machine operation. The academy offers basic and advanced seminars on the theory and practice of materials management, ensuring a thorough understanding of technology, functionality, and the impact of settings on the entire production process.

motan holding gmbh

78467 Konstanz

Germany