- 3D printing

Additive manufacturing: Industrial 3D printing with the Freeformer

Arburg at Chinaplas 2024

– Multi-material: Freeformer exhibit produces gripper in hard/soft combination

– In demand: Additive components made from high-temperature plastics and in multi-material combinations

– Versatile: Processing a wide range of original plastic granulates

Arburg's enormous expertise in plastics processing also includes solutions for industrial 3D printing from sister company ARBURGadditive. The additive manufacturing of grippers and operating equipment, for example, is an interesting option for injection moulding plants. On the Arburg stand, a Freeformer 300-3X will be producing a gripper in a multi-material combination at Chinaplas 2024.

Arburg Plastic Freeforming (APF) can also reliably and reproducibly process a wide range of original and certified plastic granules, including granules for high-temperature applications. This makes the process particularly suitable for components used in areas such as medical technology and aerospace.

Additive manufacturing of end-of-arm tooling (EOAT)

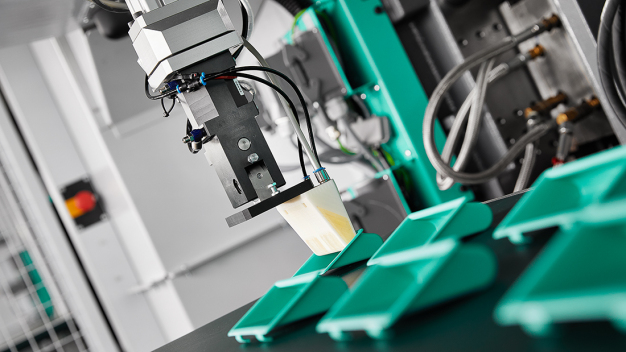

At Chinaplas 2024, a Freeformer 300-3X will demonstrate how additive end-of-arm tooling (EOAT) for various robotic systems and handling tasks can be 3D printed on demand quickly, cost-effectively and customised for specific applications. One example is a multi-material gripper, which is created in a single step with the aid of support material and without the need for any additional assembly work. The result is a resilient functional component in hard/soft combination. The hard housing is made of PC/ABS, while the soft TPE nozzle closure expands positively using compressed air to reliably remove a moulded part from the mould.

Wide range of components

The Freeformer can be used to realise sophisticated designs and complex geometries. Many examples of components will be on display at Chinaplas 2024, including products for the aerospace industry made from Ultem 9085. The Freeformer, which is suitable for clean rooms, can also be used in medical technology, for example to produce resorbable implants, breast prostheses and medical devices and aids. Customised multi-material applications such as shoe insoles made of flexible TPE and a hard zone made of PP are also very interesting. The APF process is also ideal for sophisticated AM parts made from semi-crystalline PP.

ARBURG GmbH + Co KG

72290 Loßburg

Germany