Cable gland minimizes hygiene risk

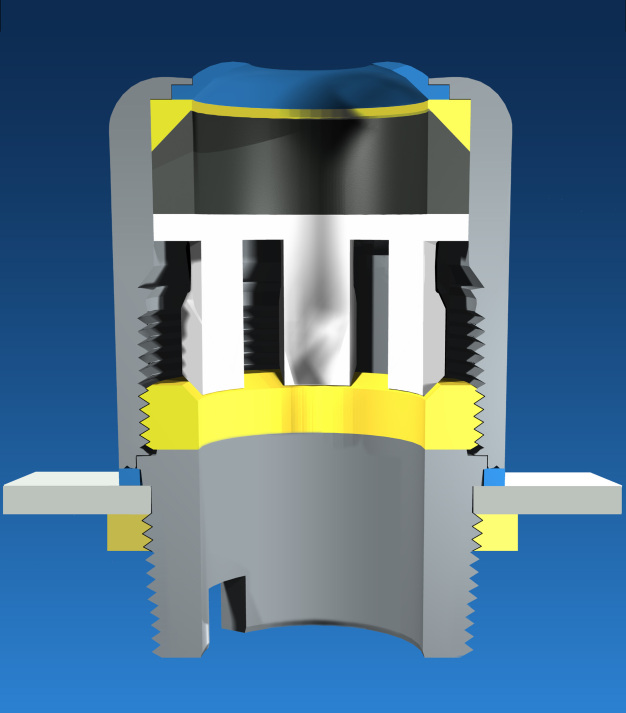

The new hygiene-fair cable gland of Rittal minimizes the possibility of deposits with � open manufacturing processes � in the food and food industry to a minimum and lowers the cleaning costs. Operators of machines and plants in the food and food industry demand increasingly from their machine manufacturers hygiene-technically optimized solutions. With its new product series � Hygienic Design � makes now its housing systems for Rittal fit for the most fastidious employments within hygiene-relevant ranges. In addition naturally also the cable gland counts, with which by consistent hygiene-fair organization the contamination risk can be reduced with the user clearly. Where conventional cable glands supply starting points for dirt nests by cavities, column and external threads automatically, only smooth surfaces are Design at again introduced ride Al design in � the Hygienic � and gentle transitions, the dirt and microorganisms no more chance offer. Special characteristic of the new cable gland is a castellated nut reaching up to the cultivation surface, which hides the complete wedging and seals mechanism under itself. This was conceived according to hygiene-fair construction criteria accurately in accordance with DIN EN 1672-2, DIN EN ISO 14159 and valid EHEDG guidelines. The transition to the housing and to the cable takes place over concisely locking seals, which are to recognize by their blue colour well and be differentiated clearly from food to. The material used for all seals is after FDA (U.S. Food and Drug administration) - guideline 21� CFR 177,2600 certified. For a safe strain relief of the imported cables a double adjustment provides over the internal poetry as well as over additional Klemmbacken.Die hygiene-fair cable gland is characterised in the further one by a high chemical and thermal stability. The used material high-grade steel 1,4305 and the seals are resistant opposite usually the cleaning and disinfectants, acids used in the foodstuffs industry and caustic solutions as well as opposite Kondenswasser.Auch the assembly go easily from the hand. Since construction dependently the outside hexagonal was void for attachment at the housing, an assembly tool takes over now this function. This is set at the lower part of the cable gland and propelled from the outside or inside over an Allen key. This makes for the first time a tightening for the nut possible from only one side. Beside the food and food industry the new Rittal cable gland can be begun also in other environments surely, e.g. in the clean-room technology (far mA and semiconductor industry), to biotechnology and with aseptischen application fields (hospitals etc.). Result: Faster and more effective cleaning with associated operating cost savings, a sinking hygiene risk and thus a safe process running off are attributes, which see to let to be able itself. The new Rittal cable gland high-grade steel Hygienic Design contributes a crucial part to it.

This text was translated automatically.

Rittal GmbH & Co. KG

35745 Herborn

Germany