interpack 2023: Digital solutions for liquid pharmaceutical processing from Syntegon

– Digital solutions provide significant time savings and safe processes

– Synexio Uptime supports the identification of optimization potential

– Modular and flexible: RMA assembly machine for clinical trials and small batches

At this year’s interpack, Syntegon will provide insights into the future of liquid pharmaceutical processing. The expert for process and packaging technology has equipped the proven ALF 5000 filling and closing machine with smart functions: from individual container tracking and an intelligent piston pump to AR-supported format changes, visitors will gain an overview of current solutions. Syntegon will also present the next stage of its cloud-based software solution Synexio, which makes it easier to identify potential for equipment and process optimizations.

Heading towards the factory of the future

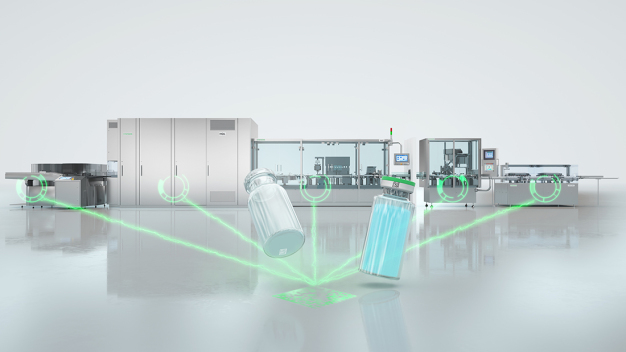

“The future of the pharmaceutical industry lies in increased automation and digitalization. Manufacturing companies need solutions that process the huge amounts of partially unused data for process optimization,” explains Daniel Sturm, Product Manager Automation at Syntegon. At interpack, the ALF 5000 filling and closing machine will demonstrate current possibilities and future potential. Amongst others, eight filling stations will show visitors which filling systems – from single-use to intelligent piston pumps – can be used with different degrees of automation.

SODA: traceability of primary packaging containers

Syntegon’s Single Object Data Acquisition (SODA) system will also be displayed on the ALF 5000. It assigns all object and process-specific data of primary packaging materials to individual batches and containers – even after they have left the machine. In combination with the smart containers EVERIC© smart from primary packaging manufacturer SCHOTT, SODA offers a very special advantage: the pre-coded containers are already equipped with a unique data matrix code that can be read via cameras. “Valuable information collected during production is assigned to individual containers and can be traced in a structured manner. This opens up a wide range of possibilities for our customers to make their production even safer and to take targeted action in the event of complaints,” says Sturm.

Significant time savings and higher process reliability thanks to digital solutions

The ALF 5000 also features an intelligent piston pump – the “Smart Pump” from Syntegon. “The pump always carries its memory with it on an RFID chip, even when it is not installed in the machine,” Sturm explains. “The system automatically recognizes the pump, for example after cleaning – which significantly increases process reliability, reduces human error, and saves a lot of time in ongoing production.” The AR solution with HoloLens glasses also ensures considerable time savings as well as fast training of inexperienced staff. Format changes can be carried out faster thanks to guided operator support. Errors during ongoing production are displayed immediately in the field of view along with virtual support.

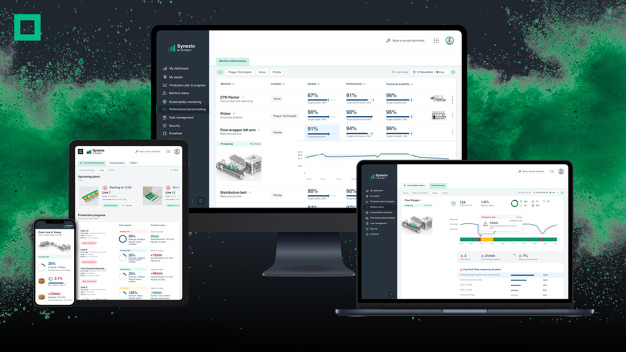

Synexio: Data transparency at all times

The new cloud-based software solution Synexio enables the acquisition, evaluation, and visualization of equipment and production data. The entry-level package “Monitor” visualizes various KPIs and creates greater transparency in production. “Our customers are already successfully using the basic package. Now it is time for the upgrade to the next level,” says Elisa Hein, Product Manager Expert Services at Syntegon. At this year’s interpack, Syntegon will present the second Synexio package “Uptime”. “We go deeper into detail with Uptime: in addition to machine availability, concrete potential for improvement can now also be determined, for example by visualizing the most frequently occurring reasons for stops,” Hein explains.

Synexio is part of Syntegon’s new Service Agreements, which form the basis for effective equipment and maintenance management at fixed prices. Seven dedicated levels enable customers to minimize production risks, make service costs more transparent, and simplify complex processes – enabling them to focus on their core business. With each level, the scope of the covered services increases, from basic service including inspection and remote service to guaranteed production performance of their machines.

The highest flexibility all along the line

The flexible Service Agreements are available for all machines from the Syntegon portfolio. This also accounts for the modular RMA (Range Manual Assembly) assembly machine for auto-injectors, pens, safety devices, and other medical devices. The pilot unit for clinical trials and small batch sizes exhibited at interpack features a workstation for manual loading and unloading of components and devices; all other process steps are carried out automatically. This way, the manual workstation achieves an output of one to three devices per minute. In addition, the hygienic design and fast format changes ensure maximum flexibility.

Versatility is also a key characteristic of Syntegon’s further portfolio for the production and processing of liquid pharmaceuticals. This includes the SVP process systems for the production of small-volume liquid pharmaceuticals, freeze dryers including a loading and unloading system, as well as flexible inspection solutions.

![]()

Syntegon Technology GmbH

Blaufelder Straße 45

74654 Crailsheim

Germany

Phone: +49 7951 4020

email: packaging-ph@syntegon.com

Internet: http://www.syntegon.com