Germ-free coils for the medical technology

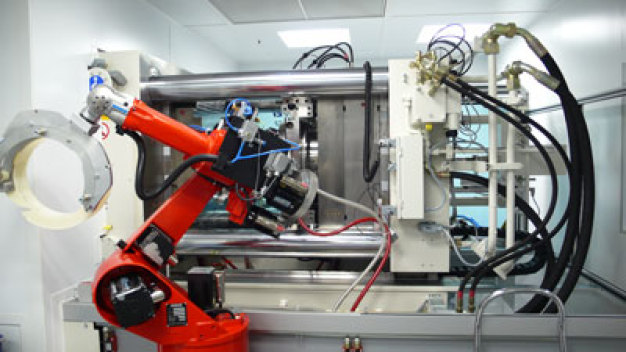

H�fner takes brown Melsungen AG to pure space manufacturing for B. aufIn only 9 months developed H�fner, specialist for plastic coils, a medical pure area. The manufacturing module is qualified in accordance with class 8 according to DIN EN ISO 14644-1 and exhibits a particle/a sterility after C � GMP* class D. Principal item of the new manufacturing module forms a pointed casting machine with 3.500 kN-Schlie�kraft.Als first product becomes two approx. 500 gr. heavy coils from impacttough ABS manufactured. The spools are sprayingpoured fully automatic in the pure area. A folding arm robot infers these parts from the tool, in order to finally destack and pack it in a double foil packing after customer requirement (picture). In the pure area ensures an operator for the supply of new packing hoses and removing the finished packing units. The coils packed manufactured in this shelter atmosphere and arrive to germ and particle-free to the customer B. brown Melsungen AG. The enterprise global represented winds on these coils � without rework expenditure, likewise under pure space conditions � capillary and hoses with diameters from 0,7 to 5.0 mm among other things for Venenverweilkan�len.Besonderheit of the pure space solution with H�fner is the complete accesibility of all substantial process controls from the outside from � the grey zone �: This is valid for the injection moulding machine, the controlling of the material supply, as well as the keeping at a moderate temperature technology for machine and tool. Complex moving and entering of the pure area with a disturbance or the change saves the setter of parameters. The structure was selected in such a way, so that humans never come with the product into contact. Result: A possible contaminating is limited to a minimum. Those unusually fast putting into production owe the coil specialists from Leopoldsh�he to its system partner, the DITTEL Cleanroom engineering from Ried/Kochel A. lake, responsible for the Design, planning and qualification, as well as the support with start-up. In the context of the decrease qualification resulted measured values, which were clearly better for number of particles and purity of the area than the demanded parameters. After information of January H�fner, are to be intensified the activities of the enterprise within this range: � the entrance into the clean-room technology opens as a coil manufacturer completely new target groups and applications to us �. For the users of coils such a Nachreinigungsaufwand is void. The coils can be directly referred germ-free. This is more economical and also safer. * (footnote) C � GMP stands for: current Good Manufacturing Practice = gegenwertige good manufacture practice of medicine products, active substances as well as food and FuttermittelBU: NO Go AREA: Withdrawal of the coils in the germ-free pure area by means of robot, that afterwards the parts stacks and packs (source of picture H�fner) �

This text was translated automatically.