- Industry 4.0

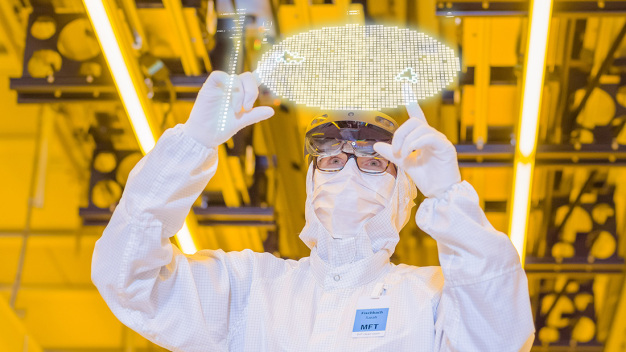

Six reasons why Bosch’s new 300-millimeter wafer fab is one of the world’s most modern chip factories

Electronically connected, highly automated production

All the roughly 100 machines and lines in the 10,000-square-meter cleanroom are electronically connected – with each other and with the complex building infrastructure by means of a central database. To make this possible, 300 kilometers of data lines were laid. Such a setup allows as many as 1,000 data channels to be recorded for each machine in real time, and relayed to a server in the plant. This centralized data architecture in the wafer fab is one of the biggest strengths of the new Bosch plant. Taken together, the production data generated is equivalent to 500 pages of text per second. In just one day, this would be equivalent to more than 42 million pages weighing 22 metric tons. One of the things this wealth of data allows is the ability to pinpoint at any time where each individual wafer is in the production process, where it is going next, and when it will arrive. The wafers are transported from machine to machine by a completely automatic system featuring individual pods known as FOUPs (front opening unified pods). Each FOUP can transport up to 25 wafers. There is no longer any manual transportation at all.

First AIoT factory

The Dresden wafer fab is Bosch’s first AIoT factory. AIoT stands for the combination of artificial intelligence (AI) and the internet of things (IoT). With this, Bosch is creating a sound basis for data-driven, continuous improvement in production, and setting new standards for Industry 4.0. Artificial intelligence methods can be used to evaluate the data generated in the wafer fab. For example, an AI algorithm can detect even the tiniest anomalies in products. These anomalies are visible on the wafer surface in the form of specific error patterns known as signatures. Their causes are immediately analyzed and deviations from the process corrected without delay, even before they can affect the reliability of the product. This is the key to further improving the manufacturing processes and semiconductor quality, as well as to achieving a high level of process stability. In turn, it means that semiconductor products can go into full-scale production quickly. Furthermore, AI algorithms can precisely predict whether and when a piece of manufacturing machinery or a robot needs maintenance or adjustment. In other words, such work is not done according to a rigid schedule, but precisely when it is needed – and well in advance of any problems cropping up. AI is also used in production scheduling, saving time and costs as it guides the wafers through several hundred processing steps at roughly 100 machines in the plant.

Plant with “digital twin”

There are two Dresden wafer fabs – one in the real world, and one in the digital world. Experts call this a “digital twin.” During construction, all parts of the factory and all relevant construction data relating to the plant as a whole were recorded digitally and visualized in a three-dimensional model. The twin comprises roughly half a million 3D objects, including buildings and infrastructure, supply and disposal systems, cable ducts and ventilation systems, and machinery and manufacturing lines. This allows Bosch to simulate both process optimization plans and renovation work without intervening in ongoing operations. Moreover, any new machinery is always delivered to the plant twice – once in the real world and once as a data model.

Looking through data glasses

In its Dresden plant, Bosch is making use of augmented reality (AR). Thanks to smart AR glasses and tablets, users will be able to see digital content superimposed on the real environment. For example, an AR app developed by Bosch allows energy data from the wafer fab to be displayed in a virtual model of the building. This makes it possible to optimize the carbon footprint of the manufacturing machinery. Data glasses also help with construction planning, and in the future will be an important aid for remote maintenance of the machinery and systems by experts who may be thousands of miles away.

5G-ready

To make the transmission of data between machines and computers even more flexible, the new 5G mobile communications standard will soon be introduced at the semiconductor plant. The plant was 5G-ready right from the start: all the requirements for 5G infrastructure were taken into consideration during the construction phase.

Carbon neutral from the start

Environmental protection and sustainability were priorities at the new location from day one. This is why the Dresden wafer fab will be carbon neutral from the outset. To achieve this, Bosch can build on experience gained at the sister plant in Reutlingen. For example, its primary energy supply is exclusively in the form of green electricity and carbon-neutral natural gas. Furthermore, sophisticated energy management ensures the best possible power consumption in its manufacturing operations.

Robert Bosch GmbH

70839 Gerlingen-Schillerhöhe

Germany