The new form of human-machine interaction in cleanrooms

Cobots enter the cleanrooms of the electronics industry. In the production of semiconductors, robots score high in reliability as well as top quality and safety standards.

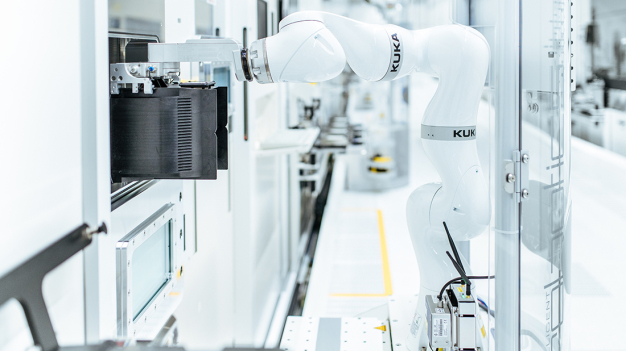

Cobots take automation in cleanrooms to a new level. In the production of micrometer-thin chips at Infineon in Villach, Austria, 17 sensitive KUKA lightweight robots work safely together with humans to ensure greater efficiency and safety when fabricating the precious and highly fragile wafers.

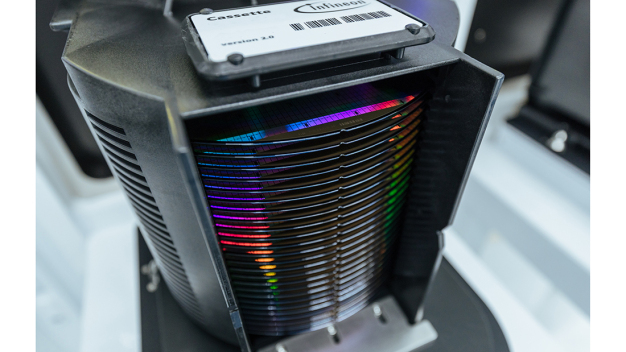

No, these silicon wafers are not really a collaborative product: at up to 40 micrometers, many wafers are thinner than a hair and yet have a diameter of 150 to 300 millimeters, which is roughly the size of a pizza. They are highly fragile and cannot be picked up by hand – even in a protective cassette. To turn these sensitive silver discs – a cassette full of which can have the value of a mid-range car – into chips, they must pass through up to 1,200 process steps. And, for each of these, they need to be transferred to a different automated processing station. A clear case for using robots.

These power semiconductors – used, for example, in cars, smartphones, refrigerators or in server farms and the traction units of locomotives – are produced at the Infineon site in Villach, Austria. Infineon Austria, a subsidiary of the German company Infineon Technologies AG, delivered 8.45 billion chips in the past fiscal year 2020, generating 3.1 billion euro in revenues. A future technology in its purest form, whose importance is also reflected in the research expenditure of 498 million euro – thus making the company one of the strongest research enterprises in Austria.

Cleaner than in operating rooms

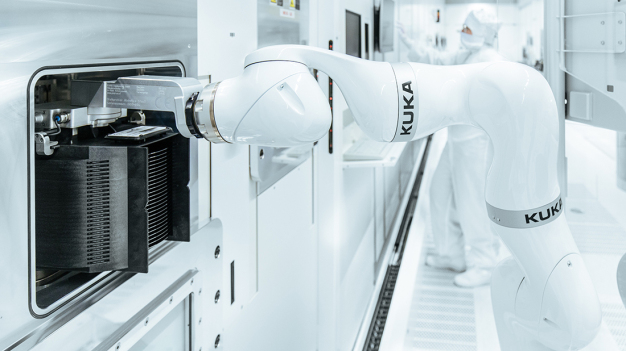

In Hall 17 of the Villach plant, Infineon produces chips on the sensitive thin wafers in a category 1 cleanroom environment. This means that in 28 liters of air, there may be no more than one dust particle. That is significantly less than what is allowed in an operating room. By comparison: in mountain air, which is considered to be particularly clear, there are roughly 100,000 particles floating around in such a volume. For the employees, this means they can only enter via a special air lock, wearing pristine white full-body protective suits. Their skin and hair must be completely covered, so that not a single dead skin cell can enter the environment. Only a small eye slot remains uncovered. Laptops and other technical equipment must first undergo meticulous cleaning. Even pens and sheets of paper for notes are custom-made, particle-free products.

“Given these extremely sensitive production conditions for our thin wafers, we have to think very carefully about which material handling technology we should use here,” explains Martin Moser, Team Leader for Automation in the AMHS (Automated Material Handling Systems) division at Infineon Technologies Austria in Villach. “Since various mobile units and also a number of people are always moving about in wafer fabrication, the use of robots is limited to systems that are extremely sensitive and designed for safe interaction between humans and machines. And all this without any protective fencing.”

Hand in hand with system partners

“In our search, we became aware of KUKA lightweight robots at Automatica,” says the development engineer. He also notes that getting the robots ready for the very special cleanroom requirements in accordance with ISO3 was an extremely intensive learning process, in which the automation experts from Infineon worked hand in hand with their system partners. In addition to KUKA, these primarily consisted of experts from Mechatronic Systemtechnik GmbH for assembly, cabling and set-up in the production facility as well as the programmers from Micado Automation GmbH for system control.

“For us at that time, there was no blueprint for the application of mobile robots in semi-conductor fabrication. We jointly tailored the systems exactly to our needs. That was real pioneering work – for us as well as KUKA,” reports Moser. This also entailed making the lightweight robots cleanroom-ready. That was uncharted territory for the KUKA robots as well. “The constructive, solution-oriented cooperation of all those involved made a significant contribution to us now having an ideal material handling solution for our automated chip production,” says Moser.

Today, 17 LBR iiwa robots perform their work in several cleanrooms – around the clock, 365 days a year. “They are extremely agile, can handle loads of up to 14 kilograms, operate without vibration and use their gripper to work with millimeter precision – even in the smallest of spaces,” says Moser, explaining the advantages of the robotic coworkers. Their additional seventh axis, in particular, allows them to execute sensitive and angular movements that “conventional” 6-axis robots are unable to perform.

Perfection down to the millimeter

Whirring quietly, they transport black cassettes full of valuable silicon wafers to the individual processing steps, feed them into the respective processing chambers with millimeter precision and subsequently collect them again. The mobile assembly robots work closely with the overhead hoist transport system (OHT, for short). Suspended on rails under the almost five-meter-high ceiling, the transport boxes float as if guided by magic to the individual stations, where they are lowered by a belt-driven hoisting mechanism. There they are picked up by one of the LBR iiwa robots in accordance with the production algorithm and transported to the next processing step.

“From the very beginning, we wanted a tailor-made solution for our production in Villach. Anything else was out of the question for us,” explains Martin Moser. “We thus took care of the integration of the systems ourselves. Here, the direct exchange with the KUKA developers was very important to us – especially with regard to how we should set up the overall system and how it continues to ‘learn’ following this.”

The right balance between the feasible and the necessary

Lisa Ebner on Martin Moser’s team has been involved in the integration of the robots into the automated wafer fabrication process from the very beginning. She has been with the company for seven years and is the expert responsible for the assembly systems. Lisa Ebner is a real fan of the mobile robots: “When I saw the LBR iiwa for the first time, as an operator back then, I was immediately and totally fascinated: I could have watched the soft, harmonious movements for hours – a pure technological pleasure.”

Watching for hours? Hard to believe. Because the automation expert, who is also studying mechatronics, systems engineering and management theory, seems almost too full of energy. She is constantly on the move in the production aisles, checking the systems at the control station and looking for further ways to perfect the fabrication process. “For optimization, we have to find the right balance between what is technically and physically possible and what makes sense for our production purposes. The closer we get to 100 percent perfection, the higher the complexity and the number of interfaces. We always have to find the right measure for cost-effective production.”

Progress through learning for future semiconductor generations

The automation team at Villach is obviously on the right track. “Everything we learn now will take us further – to the next level of automation in semiconductor fabrication,” says Bernd Steiner, Production Manager at Infineon Austria in Villach.

And in Carinthia, Austria, time is of the essence. Because the shell of a new, fully automated chip factory is already standing next to the existing production halls. Infineon has a lot planned: the company is investing 1.6 billion euro in its Villach site, making it the largest private investment in Austria. By the end of 2021, power semiconductors are to be produced here fully automatically. “Our goal is to deliver the power to exactly where it is needed in the Smart Factory,” explains Steiner. “For the energy-saving chips of tomorrow – as used in many everyday applications such as smartphones, household appliances and cars, but also in data servers, medical devices, solar and industrial systems. That will make our lives easier, safer and more environmentally friendly.”

KUKA AG

86165 Augsburg

Germany