Programming kit for SCHMIDT® current sensor Programming kit for SCHMIDT® flow of sensor

With the help of the programming kit the electrical know interfaces

river (0... 20mA or 4... mA), tension (0... 2V, 0... 5V, 0... 10V) as

well as the response time, and/or absorption (0.01... 10s) the

SCHMIDT® flow sensors SS 20,400 and SS20.415 to the employment

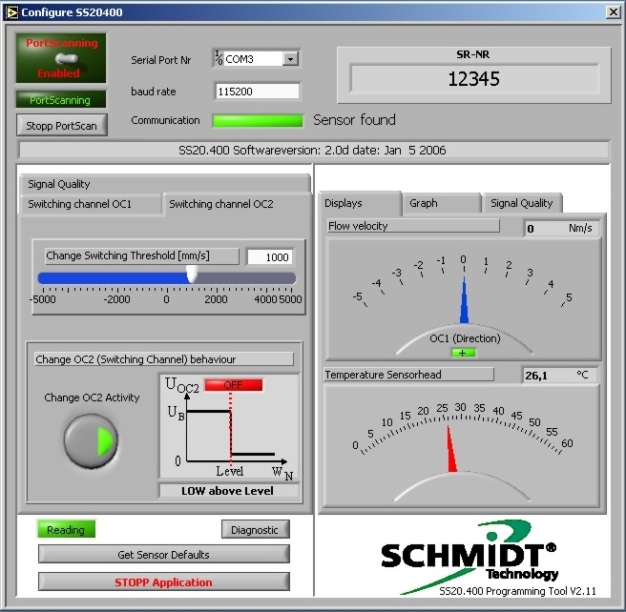

requirements to be adapted. The threshold values of the switching

exits OC1 and OC2 are adjustable between 0... 100% of the measuring

range and the switching polarity are reversible. Over the diagnostic

function all parameters can be selected and the cause for possible

disturbances be determined. To the scope of supply belong the

programming box, the RS232-Schnittstellenkabel and the user-friendly

software suitably for PC's with Windows 2000 or XP and RS232 interface

or optionally a USB connection the programming box had indicator LEDS

for the switching status OC1 and OC2 and the flow signal output.It can be supplied either via the provided 9V compound battery or via

an external plug power pack with 3,5mm mono jack plug. This

programming kits allows the analogue current outputs (0... 20 mA or

4... 20 mA), analogue volume-meets to outputs (0... 2V, 0... 5V, 0...

10V) and the response times (0.01... 10s) OF the SCHMIDT® flow of

sensor SS 20,400 and SS 20,415 tons adapted ton the operation

requirement. Trigger level OF the switching outputs OC1 and OC2 of

acres adjustable between 0... 100% OF the end to VALUE. The polarity

CAN inverted. The DIAGNOSTIC function enables ton READ the sensor of

parameter and ton find the cause OF at contingent malfunction. The

programming interfaces of includes the programming box, the RS232

interface cable and the user friendly software suitable for PC's with

Windows 2000 or XP with RS232 or optionally USB interface.The programming box is equipped with A luminous diode based display

AREA for the status OF OC1, OC2 and the flow signal output OF the

connected sensor. Power supply is integrated 9V battery or

alternatively via A 3,5 mm of mono jack socket on at eXternal barrier

power supply unit.