Autonomous Optimization Reduces Costs in Injection Molding

An example demonstrates the application of the Autonomous Optimization tool available in SIGMASOFT® Virtual Molding. The mold for a thick-walled part had to deliver a cycle time below 60 seconds, which could be realized with different tempering concepts. The best cooling configuration was found at the lower manufacturing cost.

Tempering problems account for around 60% of the total of quality issues in injection molded parts. With an ever increasing pressure on individual part costs and shorter mold development deadlines it is imperative to produce affordable, reliable and efficient mold solutions within the shortest possible time.

A new tool, released at Fakuma 2017 for the first time, allows mold makers to virtually identify the most efficient solution in their designs. SIGMA Engineering GmbH (Aachen, Germany) has released the Autonomous Optimization solution as part of its SIGMASOFT® Virtual Molding software. It helps the user to find the best possible solution out of all the possible combinations of a parameter set.

A base for an office roll chair had to be produced. The mold maker was confronted with the problem of designing the most efficient mold possible at the lowest cost. A cycle time below 60 seconds was targeted.

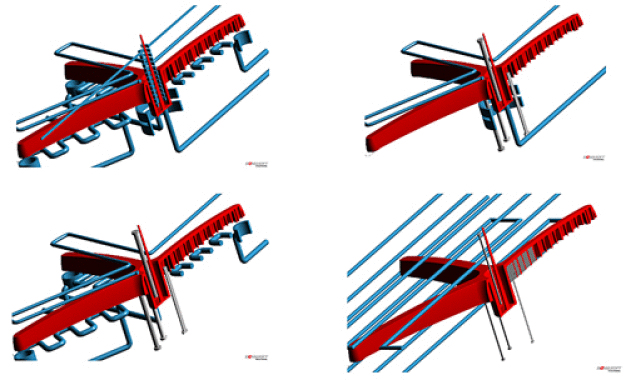

The mold maker selected the different parameters which he could vary in the mold to achieve the requested cycle time. The mold material, the layout and diameter of the tempering channels, a conformal cooling concept and high-conductivity pins were selected as the variables. All the possible combinations of these variables gave a total of 40,000 different mold configurations. The autonomous simulation tool worked to find amongst these possible scenarios the ones that released a cycle time below 60 seconds.

Amongst the different possible design combinations delivering the target cycle time it was then possible to filter the ones with lower cost. For this particular application, it was found that conformal cooling was not necessary, and that the required heat dissipation effect to achieve the targeted cycle time could be obtained using high-conductivity pins with 4 mm and 10 mm in diameter. The required diameter in the water channels was found to be 6 mm.

The Autonomous Optimization available in SIGMASOFT® Virtual Molding is able to find the most effective mold design at the lowest possible cost. Not only cycle time can be optimized, but also part deformation, energy costs and molding defects can be minimized through the identification of the optimum parameter combination.

SIGMA Engineering GmbH

52072 Aachen

Germany