Production technology for even the smallest parts

Gerresheimer at MedTec China

Miniaturization is one of the most important technology trends in medical technology. Increasingly smaller and more precise components are required for the construction of medical devices. The conventional injection molding technology reaches its limits when it comes to the production of such parts. Gerreheimer Medical Systems therefore uses a special micro injection molding technology, with which extremely small parts can be produced in a precise and economic manner.

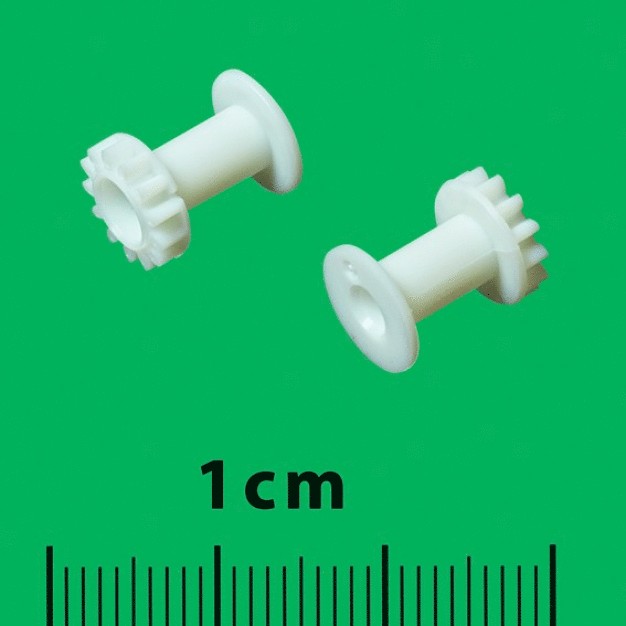

Some micro-injection-molded parts are smaller than the tip of a pen. When producing such products in accordance with the specifications, we have to master challenges in the areas of tool systems, injection molding technology, and measurement technology. Molds must, for example, adhere to much smaller dimension tolerances than the parts produced in them. The mold making department at Gerresheimer therefore uses very special machinery, which is capable of milling and polishing up to a precision of 2 micrometer. In addition, it is ensured that the developed mold solutions can easily be scaled in series production from small platforms for micro-injection molding machines to larger platforms for standard injection molding machines. (see fig. 1)

Due to the small shot volume, traditional injection molding machines cannot easily be used for micro-injection molding. If the plastic remains too long in the plasticizing aggregate and in the hot runner system of the mold, the material may degrade. In addition, the required mechanical precision is difficult to achieve with technology designed for much larger parts. Gerresheimer offers two solutions for this challenge. Large series are manufactured on modified standard injection molding machines. Heavily utilized molds ensure a shot volume which prevents any material degradation. Optimized special screws and non-return valves ensure the required precision. When producing small to mid-sized series, as well as products with particularly high precision requirements, Gerresheimer then uses special micro-injection molding machines. Here, the screw is only responsible for the plasticization of the plastic; the injection is performed by a piston in an extremely precise manner. (see fig. 2)

The third challenge is possessing the measuring technology suitable for micro-injection molding parts. At the Technical Competence Center in Wackersdorf (Germany), Gerresheimer has a computer tomograph at its disposal. A special technology is used there for the measurements. The technology is able to reliably fixate and display even the smallest objects during the measurement. Similar equipment is used for the optical measurements as well. In addition, the measured geometry must be freely accessible. With these two measuring technologies, it is possible to obtain measurements for the validation of molds and to manage quality quickly during the ongoing manufacturing process with the necessary speed.

Gerresheimer will be represented at MedTec in Shanghai from September 22-24 at the Shanghai World Expo Exhibiton & Convention Center, booth no. P301.

Gerresheimer AG

40468 Düsseldorf

Germany