Pack medical items flexibly and reliably

MULTIVAC at Medtec 2015 in Stuttgart

From 21 to 23 April 2015 at Medtec in Stuttgart, MULTIVAC will be presenting thermoforming packaging machines, traysealers, special chamber machines and labellers for packing small to medium-sized batches. All the models, which will be exhibited in the “Medical Packaging” theme pavilion on Stand 7F10, are characterised by their high level of precision and flexibility.

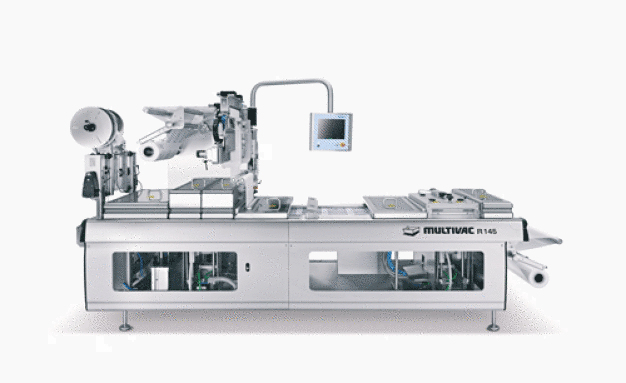

The entry-level model of thermoforming packaging machine that will be on show is designed for small batches, and it can be used for running both flexible and rigid films. It is ideally suited to packing sterile medical products and cosmetic items. This compact model is aimed at companies, which want to embark on automatic thermoforming pack-aging or run small volumes. The second thermoforming packaging machine is designed to produce high-value packs in the small to medi-um-sized output range. A quick-change system for the forming and sealing dies makes conversion to other pack formats very easy, and the optimised lifting units ensure that there is a consistently high and re-producible pack quality. Thanks to the various equipment options avail-able, this machine can be adapted to individual requirements. Both ma-chine models can produce packs with modified atmosphere and con-trolled residual oxygen content, as well as being able to run a wide range of packaging materials.

For tray packaging requirements, MULTIVAC will be presenting the T 260 traysealer, which is a packaging system that has been developed for the specific demands of the medical sector and pharmaceutical in-dustry. It supports GMP-compliant packaging especially with regard to packaging quality, process reliability and cleanroom compatibility. In order to achieve consistent pack quality, the T 260 is equipped with a specially designed sealing die, which ensures that controlled sealing pressure and precise temperature distribution are maintained.

Temperature-controlled sealing bars also ensure that reproducible seal quality is achieved on the C 200 TC and C 300 TC special chamber machines (TC=thermo controlled). Both models can be calibrated and validated, and they meet all the legal requirements as well as the GMP, GAMP5 and ISO guidelines. The two cleanroom-compatible chamber machines are also suitable for a wide range of pouch materials, and they can produce packs under vacuum or modified atmosphere (MAP) with controlled residual oxygen content.

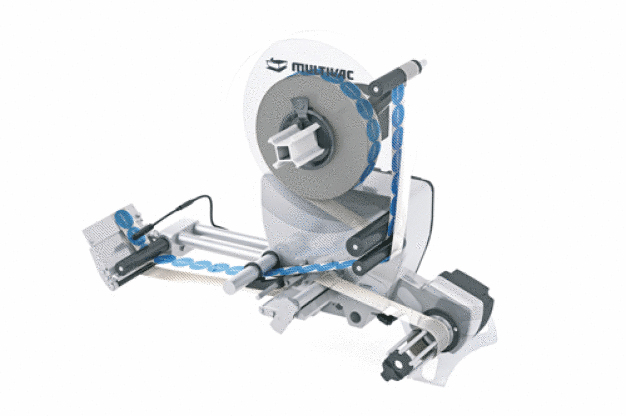

The LD 100 label dispenser can be equipped with various printing sys-tems, such as for example thermal transfer, inkjet or hot foil printers. Since the labelling units are constructed in a modular way, they can easily be adapted to different labelling tasks. The labeller is characterised by its high level of transport accuracy and its small tolerances with label positioning. Thanks to the integration of camera systems, it can be ensured that only those labels are applied, which meet the required standards.

MULTIVAC Sepp Haggenmüller GmbH & Co. KG

87787 Wolfertschwenden

Germany