The Drops of Life

Breastfeeding research has been instrumental in the development of Medela’s world-leading range of breast pumping and feeding solutions.

“Most health research focuses on just a few areas, such as cancer or Alzheimer’s disease,” says Martin Elbel, Head of Corporate Communications at Medela AG. “This is obviously vital but it means that hardly any money goes to fields like breastfeeding or lactation. Little attention is given to the beginning of life.”

Medela, a manufacturer of breast pumps and breastfeeding products, has therefore funded research into breastfeeding and human milk for almost 20 years.

“Funding is into basic research not directly connected to our products,” continues Elbel. “This may lead to applied research and, though rarely, eventually to product development and subsequent clinical research. Basic research influences the development of new solutions.”

Medela has a long-standing relationship with the University of Western Australia (UWA) and also collaborates with other universities, hospitals and research institutions globally.

“Though human milk has been produced and breastfeeding has existed as long as the human race, it is amazing that we still discover something new,” says Elbel. “For instance, recent research has identified stem cells in human milk that display a similar morphology with a similar gene expression to human embryonic stem cells.

These pluripotent human breast milk stem cells can differentiate into other types of cells, including brain, liver and pancreatic cells. This stem cell research is very exciting and could potentially be lifesaving in the future.”

There are more than five times as many components in breast milk as in formula and no formula can duplicate the properties of breast milk. The World Health Organization recommends that mothers breastfeed their babies for six months.

The benefits of breastfeeding are numerous. The baby receives nutrition exactly as required and breast milk prevents growth of certain harmful intestinal bacteria. This reduces infections and there are clear signs that it decreases the risk of allergies, cancer, diabetes and obesity later in life.

Despite the benefits, attitudes to breastfeeding vary in different cultures and countries. In China, for instance, breastfeeding was not encouraged for a long time. Medela, working in close cooperation with the Ministry of Health and specialists, helped to gradually change the attitudes of hospital professionals to breastfeeding and to make a positive impact on the mindset of millions of people.

Applied research in product design has led to development of solutions that maximize effectiveness of breast pumping and feeding systems for babies.

“Ultrasound proved the conventional representation of the anatomy of a lactating breast was incorrect,” says Elbel. “Within the breast there is a complex network of ducts. These and glandular tissue branch closer to the nipple than used to be believed. The diagram of the lactating breast developed from research funded by us is now the standard used in text books and on the web.”

Discoveries on the way that babies suckle have directly influenced Medela’s products. Its breast pumps re create the two phases in which babies nurse. Initially babies suck fast and shallow to stimulate the milk ejection reflex, then switch to a slower and deeper suck.

“We worked with Professor Peter Hartmann, an internationally renowned specialist in the field of breastfeeding and milk synthesis and his Human Lactation Research Group at UWA. Since the mid-1990s, Medela has applied Hartmann’s breakthrough research, which finally resulted in the development of an exclusive pumping pattern called 2-phase expression. It closely mimics a baby’s natural nursing rhythm to maximize milk output when using a breast pump.”

A new key focus area for Medela is the feeding of breast milk to premature babies. Though the benefits of breast milk are even more important to preterm infants, they are often not capable of feeding from the breast at birth, and even when they are, the mother’s body may not be ready to give sufficient milk.

“Often a premature baby will need to be fed enterally and with a bottle,” says Elbel. “However, feeding from a traditional feeder is nothing like feeding from the breast.”

Through ultrasound imaging research it was discovered that milk flow is influenced by a vacuum produced by the baby through specific tongue movement.

“Analysis of the way babies suck and take milk from the breast led to the development of two similar feeding systems, one for term babies and one for use with premature babies,” continues Elbel. “The teat of our Calma and our C almita incorporates a vacuum-controlled valve that only triggers a flow of milk when the infant moves their tongue downward to create a sufficiently strong intraoral vacuum in the same way as the maternal breast opens the milk passageways under those conditions.

“Calmita teaches a premature baby how to suck properly, making it easier for the baby to transfer to the breast and encourage maximum milk flow from mum. This combined with effective breast pumping to stimulate milk production, even in mothers who are not quite ready, can mean the premature baby can benefit from their mother’s milk as soon as possible and in as high a volume as possible.”

Innovative manufacturing processes

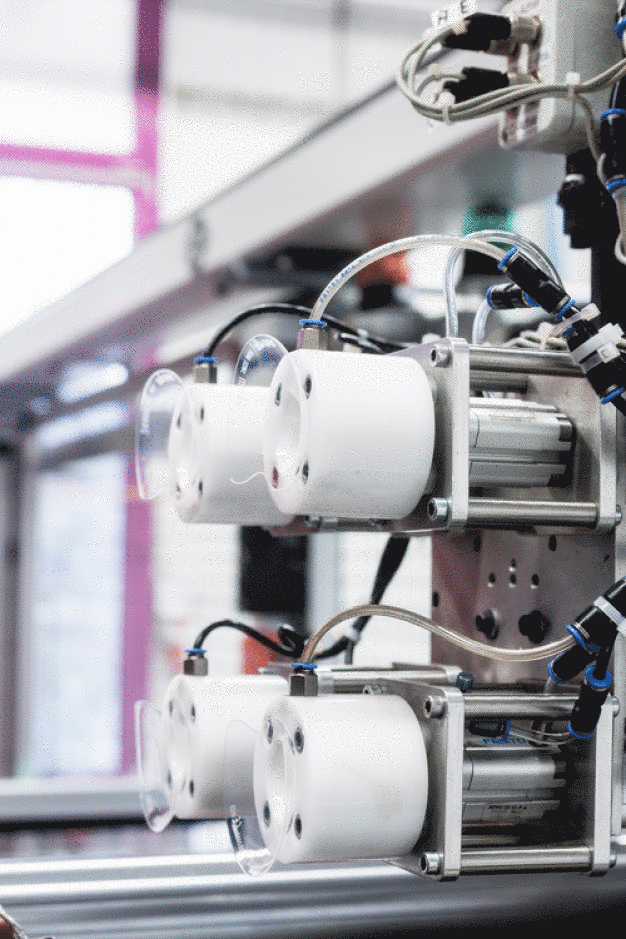

Trelleborg Sealing Solutions molds silicone breast shields for Medela’s world leading range of breast pumping and feeding solutions. The silicone component is accurately tooled to ensure the finest flash-free hole in the shield and is produce d in a dedicated cleanroom on a specially developed injection molding machine.

One hundred percent in-process quality checks combine with specialized pick-and-place manufacturing to transfer the product from machine to packaging without any manual contact that could impair the breast shields’ super-clear finish and ensures high volume demands are met.

Silicone Solutions

Trelleborg Sealing Solutions in Stein am Rhein has been a supplier to Medlea from the early 1990s and has contributed to the component design of over 40 engineered-molded silicone components for Medela’s breastfeeding solutions, including numerous parts for its breast pumps and silicone breast shields.

“Both companies are connected by good an intensive cooperation in daily business, but also in the continuous improvement of products and in new projects,” says Gotthard Suter, Streategic Producrement Manager at Medela. “We see Trelleborg as a professional liquid silicone rubber manufacturer with a full tool box of know-how in production. Collaboration is close on designs and Trelleborg will always come up wioth a variety of options in component design and manufacturing processes.

“Quality is vital in our breast pumping equipment, and from Trelleborg this is high and stable. The components we require are never simple but Trelleborg is able to effectively meet our requirements for complex solutions.”

Trelleborg Sealing Solutions Silcotech AG

8260 Stein am Rhein

Switzerland