SIGMASOFT® Virtual Molding presented at Kunststoffen 2014

Virtual Molding Increases Profitability of Injection Molders Substantially

At the upcoming Kunststoffen 2014, Booth 186, SIGMASOFT® Virtual Molding is presented. As it accurately reproduces the complete injection molding process in the computer, possible production problems are found and solved inexpensively, while security is increased for the important decisions.

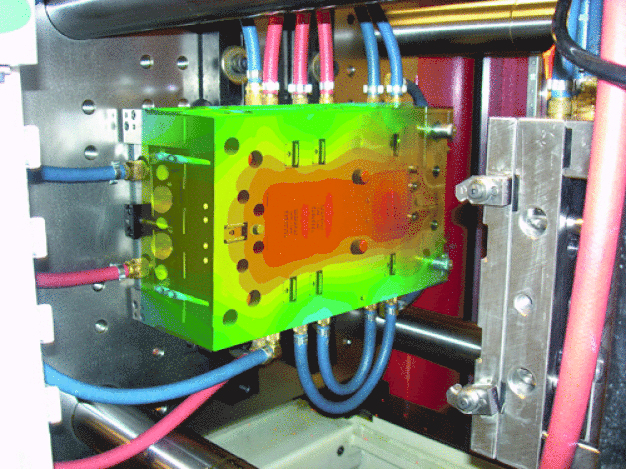

SIGMA Engineering GmbH presents at Kunststoffen 2014 (Veldhoven, Netherlands, September 24th and 25th, 2014), Booth 186, its SIGMASOFT® Virtual Molding technology. The technology, based on over 25 years’ experience in development of scientific-technical software, reproduces in all detail the complex interactions between polymer, mold and process times, successfully replicating the relevant parameter which determine process efficiency and part quality. The user identifies the root causes for problems in injection molding already upfront and establishes a deepened understanding of the molding process. Thus significant economic benefits are achieved and come along with increased part quality, process stability and processing competence, i.e. the detailed technical knowhow about the own applications.

The process-experienced user has almost endless application possibilities with SIGMASOFT® Virtual Molding. As an intuitive to use tool it accompanies the whole process – from part design, through mold design optimization, determination of the processing window, up to process fine tuning and continuous process optimization – to increase productivity and save costs from day one. This works, because the user of SIGMASOFT® Virtual Molding integrates the complete mold design, with all components, its material properties and the relevant process parameters into his analysis and varies them according to his requirements and boundaries. Consequently all interactions in the system are reproduced at every time step and location, and possible problems regarding article quality, cycle time and economic efficiency are identified timely. Thus the user early understands all potential weaknesses and has time to work on effective solutions, which finally results in robust molds and robust production processes. To build the mold and wait for mold trials to rework the mold is no longer required. These old-days iterations are minimized by users of SIGMASOFT® Virtual Molding and customers permanently report iteration-free starts of production.

Besides the obvious economic advantages, first adopters again and again are surprised about the achieved process stability and how their deepened process competence is appreciated by their customers. Especially the relation between OEM and molder is further tightened – on a mutually beneficial, fair level. As several mold concepts can be tried inexpensively within days, it is possible to find an optimum configuration, and to properly communicate decisions along the development chain. And while more information about real cycle time and mold productivity is available, now mold quotations are more transparent and save. Decisions are based on sound technological background, which benefits the company reputation.

SIGMA Engineering GmbH

52072 Aachen

Germany