New order for auto injector production

Gerresheimer produces drug delivery device for a leading pharmaceutical company

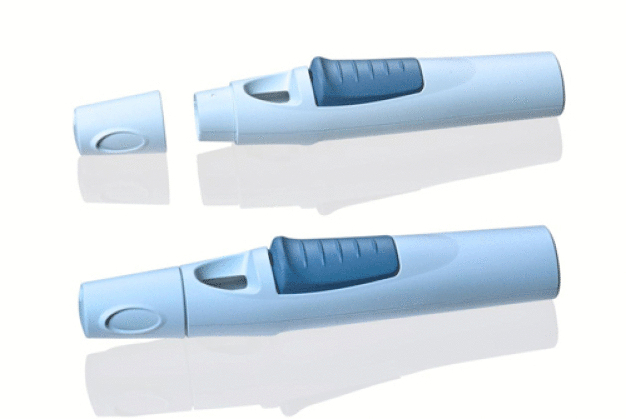

A leading US pharmaceutical company commissioned Gerresheimer with the production of auto injectors. The drug is prescribed for the treatment of moderate to severe active psoriasis arthritis. Gerresheimer produces the plastic components at the Medical Plastic Systems division’s production site in Kuessnacht, Switzerland.

The auto injector consists of fourteen plastic components and three metal parts. Gerresheimer produces the plastic components and joins them with the metal parts to create two sub-assemblies, which are assembled by the customer and loaded with the drug. The production lines made by Mikron were supplied by the customer for reengineering and industrialization. Gerresheimer developed and produced the required multi-cavity molds; a 650 sqm ISO class 8 cleanroom at the Kuessnacht site was put into operation for the first time and molds and lines also underwent qualification. The production started in January 2013. For the customer, Gerresheimer’s expertise in the area of injection and the wide range of services made them the perfect choice.

Psoriasis is a chronic illness which leads to inflammation and scaling of the skin. The causes of this disorder are complex and have not been researched conclusively, however, malfunction of the immune system has been identified as playing a major role. About one third of psoriasis patients also suffer from psoriasis arthritis with swollen and aching joints. In severe cases, the affected joints are permanently changed or damaged. Psoriasis arthritis is commonly treated with the drug (active ingredient: Golimumab) which contains monoclonal antibodies that help control the malfunction of the immune system. Once a month, the drug is injected subcutaneously by patients using an auto injector.

Since 2007, Gerresheimer’s Medical Plastic Systems division became a global strategic partner for the customer. At present, Gerresheimer operates the large-scale production of medical plastic systems for customer’s device, diagnostics and pharmaceutical divisions at five of its total of six production sites that cater to this area in Europe, the US and Asia. The Technical Competence Centers in Wackersdorf (Germany), Peachtree City (USA) and Dongguan (China) also work in close cooperation with the customer. The TCCs act as partners for the entire process chain from development right through to mold engineering, automation and preparing the product for large-scale production. For the customer, the integration of Gerresheimer’s special expertise at an early stage means that envisaged budget is not exceeded, technical challenges involved in the manufacture of innovative products can be solved, critical quality-related aspects can be identified and risks can be minimized. In addition to the business unit Medical Plastic Systems, the customer also has business relations with Gerresheimer AG divisions such as Primary Packaging Glass and Plastic Packaging.

Gerresheimer AG

40468 Düsseldorf

Germany