SIGMASOFT® Virtual Molding at Maplan Days of Technology 2014

Virtual Injection Molding Machine reduces costs in rubber injection molding

In a 40 minute presentation the application and potential of SIGMASOFT® Virtual Molding for rubber injection molding industry will be presented. Shortened time-to-market, improved mold tempering, optimized cold runner design, reduced energy consumption and reduced cost-per-part are some of the achievable advantages.

Between the 4th and 5th of June 2014, Maplan will host their in-house show “Maplan Days of Technology”, an exchange platform on the topic of elastomer injection molding. The event will take place in Ternitz and Vienna, Austria, with technical presentations and booths exhibiting solutions for automatization, quality control, application engineering, energy efficiency and cost reduction.

“We are proud to be invited to this prestigious event, to share with existing and potential customers our latest technological developments for the rubber industry”, explains Dr. Marco Thornagel, Executive Director at SIGMA Engineering GmbH. “With SIGMASOFT® Virtual Molding we have developed a unique tool to support quality assurance, to reduce energy consumption and to minimize costs in elastomer injection molding”.

On the first day, Wednesday 4th at 14:00, SIGMA Senior Engineer Tobias Mansfeld will give a presentation on the topic “Virtual Molding of Elastomer Parts” in the English session. On the second day, Thursday 5th at 16:00, the same presentation will be repeated in German under the title “Virtueller Spritzguss von Elastomerformteilen”.

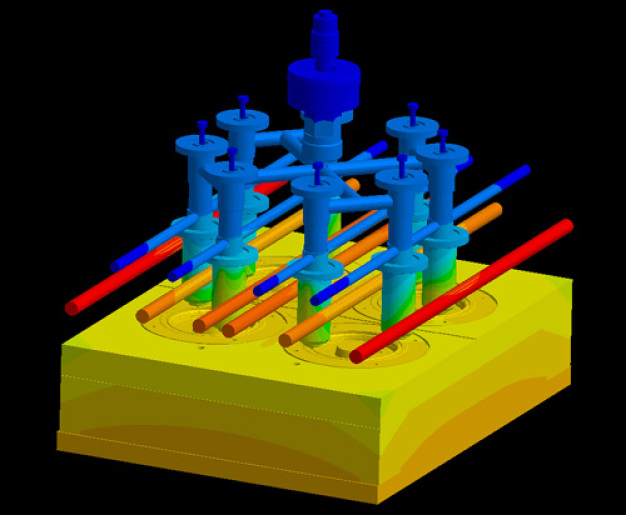

SIGMASOFT® Virtual Molding was first presented at the past K-Show in Düsseldorf, in October 2013. Following a unique approach, it reproduces the complete injection molding process, including all mold components with their complete thermal and physical interactions over several cycles, to predict the real mold performance and its effect over part quality, cost and cycle time.

“The result is that you can now try all iterations virtually, instead of doing it on a real mold”, explains Dr. Thornagel. The conventional approach when developing a new rubber part is to design the injection point, the runner geometry and the tempering layout in the mold based on previous experiences. This approach, however, normally requires iterations; when the mold is ready, it is mounted on the machine for its first trials, and usually undesired results are found, requiring tool tweaking and rework. As SIGMASOFT® Virtual Molding reproduces exactly all the phenomena appearing in real injection molding, it can show the outcome of each iteration. Several mold configurations and process set-ups can be tried upfront. “This way, the machine is used for producing, and not for fine-tuning”, explains Dr. Thornagel. “You only produce a mold once you are sure to have the optimal configuration, as on the computer you can now visualize how a mold will work in real life”.

Early adopters of SIGMASOFT® Virtual Molding have revealed overwhelming results: they get first-shot success on the molds produced, with no further iteration required. “A team can now virtually try different configurations, and decide based on physical results whether they will work or not and, most importantly, why”, explains Dr. Thornagel. “Possible issues compromising part quality can be early identified and corrected, and the team can gain confidence to compromise with new projects, as they have now a powerful tool to back them up”, he adds. “We have built a smooth and easy-to-use interface, with language familiar to process-skilled people and an automatic intelligent meshing system, so that the software works for the rubber process engineers, and not the other way around”.

With SIGMASOFT®, SIGMA Engineering has been attending the needs of rubber injection molding since its very beginnings in 1998. “We know that rubber molding is a science by itself, and deserves targeted material models, able to reproduce complex material interactions. We are committed to excellence in rubber molding, knowing that only through continuous technological investment we can aid our customers increase their competitive edge and profitability. This is why our offer complements the one of our prestigious partners at Maplan Days of Technology”, declares Dr. Thornagel.

SIGMA Engineering GmbH

52072 Aachen

Germany