Spang & Brands combines know-how in new technology center

MEDTEC, Stuttgart/Germany, June 3 – 5, 2014, Hall 5, Stand 5E61

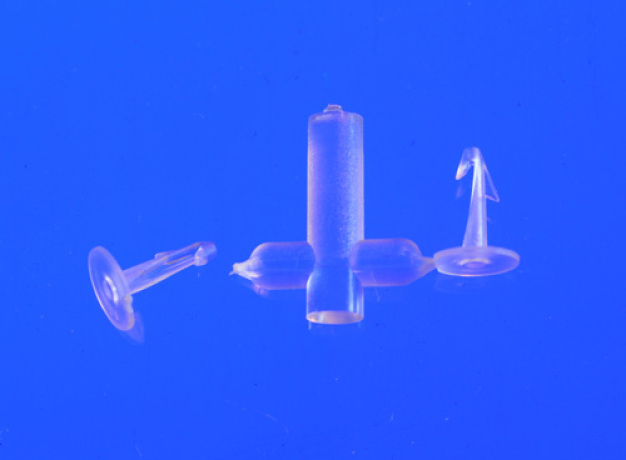

Medical technology is not exempt from increases in customer requirements. Precision components are getting smaller and require ever tighter tolerances. Although medical devices are increasingly easier to handle and thus more patient-friendly, their complexity is yet becoming more and more demanding. The commitment, from design to products being ready-for-manufacture is on the rise. Components, such as, for instance, the miniaturized fix element (see photo, page 2), are to reach the production stage and be ready for market in the shortest possible time span. Over the past few years, Spang & Brands GmbH has been taking increased customer expectations fully into consideration with targeted investments in software as well as hardware.

Always looking at how to benefit customers, the company has taken further steps into the future of medical device innovation by increasing its efficiency and by combining its specialist know-how. During June, the MEDTEC month, the company will inaugurate a new technology center. Flat organizational structures, geared to maximize performance-driven expertise, can then flourish under one roof, a concentration of the entire range of core competences, including state-of-the-art hardware.

“Now we have an integral facility covering more than 2,500m². The performance chain begins with the initial idea, in other words product design, seamlessly moves to the precision mould manufacture, then to trials with new materials or material blending and to special assembly methods. At the end of the development phase we reach production sign-off, including clean-room injection moulding technology, and final customer validation”, according to Friedrich Echterdiek, managing director at Spang & Brands GmbH.

The CAD development and design division is located on the first floor of the new center. Here, new products are given their three-dimensional shape. The precision mould making division occupies some 1,000m² of the entire facility. The adjacent mould trial section houses several injection moulding machines, including fully electric IMM with clamping forces of between 30 and 150 tons. Documented quality control routine, according to the strictest possible guidelines, is essential for product optimization, including the validation process. Special assembly can be found in the adjoining clean-room, mainly for manpower-intensive products which cannot yet be assembled fully automatically. “In this center the entire breadth of know-how functions is concentrated in one facility – from the initial idea to the product and, finally, to the production process”, emphasizes Echterdiek. Also incorporated is the department to thoroughly train the next generation of experts. For the first time, training to become a fully qualified product designer is available here.

Spang & Brands GmbH is a DIN ISO 13485 certified company. The new clean-room conforms to GMP (Good Manufacturing Practice). “In a further expansion phase, we are planning to enlarge and upgrade our machine pool. That will be the second step following our move to the new center“, explains the managing director. “With these steps the course is set to produce ever more sophisticated medical devices in the future. In accordance with this, we will be sustainably flexible, be that our know-how, manpower, our technology and capacity. At MEDTEC in Stuttgart customers can convince themselves of our capabilities.”

During MEDTEC, Spang & Brands will exhibit a broad range of medical devices in Hall 5, Stand 5E61, ranging from precision and micro products in mono and co-injection moulding technology, moving on to disposables, syringes, cannulas, tamper-proof membranes and parts for implants, through to components for minimally invasive medicine. Furthermore, connectors, functional parts for intravenous drip solution bags and closure systems are on display, not forgetting assembly-intensive devices and ready-for-sale units.

Spang & Brands GmbH

61381 Friedrichsdorf

Germany