Phillips-Medisize – Anniversary during the MEDTEC Year

MEDTEC, Stuttgart/Germany, 3rd to 5th June 2014, Hall 5, Stand 5B40

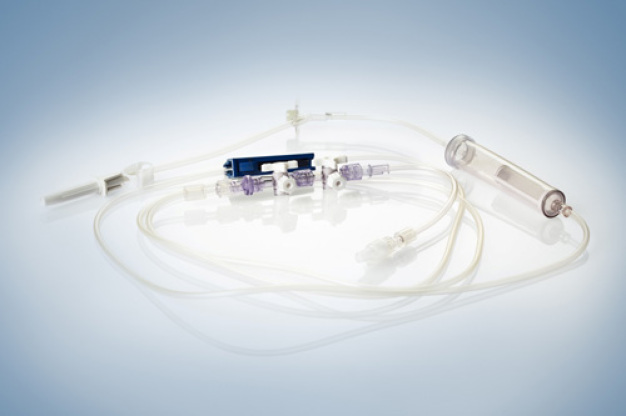

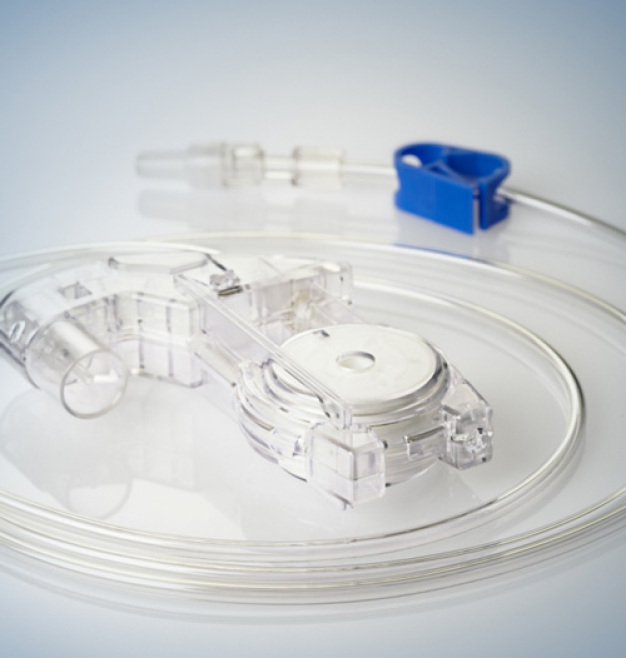

For the areas of medical device technology and diagnostics at MEDTEC in Stuttgart, 3 to 5 June 2014, Hall 5, Stand 5B40, Phillips-Medisize will present solutions for the development and manufacture of medical devices made of plastics: From disposable insulin pens, blood glucose meters, inhalators, IV sets, peristaltic pumps, titre plates, mixing injectors, consumables for diagnostic components, all the way to complete MDD application sets. Phillips-Medisize offers their customers a complete service chain, from the idea to the finished solution, from the design stage all the way to the ready-to-use sterile-wrapped medical product. The company’s strong point in the market is represented in particular by complex disposables, controlled across all processes through highly prioritised quality assurance measures compliant with ISO 13485 as well as with FDA standards and GMP (Good Manufacturing Practice).

Anniversary during the MEDTEC year: After having been around for 50 years, the Phillips-Medisize Corporation continues to concentrate on offering its customers an integrated chain of service with particular focus on GMP. The leading global outsourcing partner for product development and manufacture for the Medical and Pharma industry is determined, in cooperation with its customers, not only to maintain the standard of quality it has achieved, but also to expand it. As Matt Jennings, president and CEO, recently noted, the anniversary year 2014 represents a significant milestone in the company’s development. “During the past 50 years, together with our customers, we established a cooperation based on fairness and partnership. Quality, innovation and service have always played a major part in this. The success of the partnership is based on sustainable investment in our employees, our processes know-how, our plants, and our equipment. This is how we were able to develop an outsource design, development and manufacturing business that is unequalled across the globe,” Jennings remarked. This type of organisation made it possible for customers to integrate their own product designs into Phillips-Medisize’s comprehensive injection moulding and assembly services.

Not too long ago, Phillips-Medisize substantially expanded its business in Europe. Moreover, overseas as well – especially in China and Mexico – the company made some strategic acquisitions. Through its expansion strategy, Phillips-Medisize essentially wants to help customers shorten and strengthen their supply chains. At the same time, uniform standards are to be established globally. Locally, there will be comprehensive engineering services and flexible manufacturing options. Providing the customer with a solid platform within reach, to be able to produce top-quality products together with a pool of competent and talented employees, is the objective of all activities. Particularly in the Netherlands, the Czech Republic, and in Finland, Phillips-Medisize continues to increase its presence further. In the Netherlands, the company enlarged a building complex for the manufacture of medical and diagnostic devices in early 2014. Some 1,200 m2 of an expansion area of 1,600 m2 are reserved for various classes of cleanrooms. Here, 11 additional injection moulding machines – clamping forces between 35 and 260 tons – are taken on duty. In the Czech Republic, the company is expanding its production area by approximately 1,000 square metres – for clean room production, which is gaining in importance in Eastern Europe. The largest European investment was made in Finland, an expansion by an additional production area of 6,000 m2, to meet the increasing demand for drug delivery devices in Europe from a single source. For this purpose, the company built cleanrooms up to ISO class 8 and assembly halls for injection systems.

In January 2014, Phillips-Medisize announced that it had signed a cooperative agreement with Sanofi for the delivery of insulin pens – a significant success of its expansion strategy. The enlarged Finnish plant is manufacturing single-use systems for this long-standing pharmaceutical enterprise that are to be sold in Japan and must meet that country’s strict quality requirements. Phillips-Medisize met these standards by virtue of its knowhow in assembly technology. The pens are being made using the injection moulding process with subsequent fully automated assembly. For Matt Jennings, this project is a typical example of innovative cooperation, based on the Phillips-Medisize premise of having everything, from mould making to automation technology, under one roof in order to provide the customer with comprehensive service.

Phillips-Medisize Corporation

8309 Nürensdorf

Switzerland