Bego is expanding its Surface Technology Centre in Bremen

Surface technology and packaging of dental implants in clean room conditions

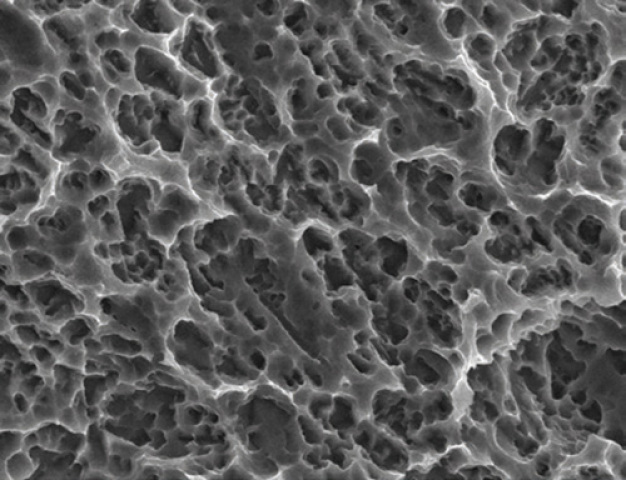

With the start of the New Year, Bego Implant Systems inaugurated the expanded Surface Technology Centre at its headquarters in Bremen. This will mean that Bego Semados® implants can be fabricated under strict conditions in the modernised clean room, and then immediately packaged in the low-germ, low-particulate environment. The core process is the subtractive finishing of the implant blank through various treatment steps to produce a defined roughening of the surface, ensuring optimal osseointegration. The quality features are the defined, homogeneously distributed surface roughness and its purity.

The modernisation and expansion of Bego's Surface Technology Centre comes in response to increased demand, especially from international markets, for Bego Semados® implant systems and the associated prosthetic components.

The fabrication and processing of dental implants demands high purity standards, which the Bremen-based dental specialist goes a long way to satisfy. For example, access to the clean rooms is restricted to specially trained staff and is only possible via an airlock. As soon as surface finishing is complete, the implants are transferred via a separate airlock into the new clean rooms, which comply with the requirements of ISO 14644, CL. 7 / EG GMP C. There they are fine-cleaned and undergo a final examination under the video microscope before being packaged under clean, low-germ conditions.

All the implant systems in the Bego Semados® product range are given the proven TiPurePlus surface finish. This entails sandblasting and etching the implant blank, which is made of Grade 4 commercially pure titanium, using a special, precisely defined technology.

The Bego Implant Systems GmbH & Co. KG, certified according to ISO 9001, ISO 13485 and Directive 93/42/EEC. By expanding its Surface Technology Centre in Bremen, the company has underlined its field of competence and demonstrated its experience in the development and production of system solutions for all aspects of dental implantology.

Bego Implant Systems has its head office in the Technology Park at the University of Bremen. Here, Bego's team of highly qualified scientists from a range of disciplines and engineers and technicians specialising in diverse subject areas are able to access other modern laboratories and research establishments in addition to their own in-house technical facilities.

BEGO Implant Systems GmbH & Co. KG

28359 Bremen

Germany