Virtual Molding Saves Costs in Rubber Injection Molding

A case study about the use of Sigmasoft® in rubber processing

In a 48-cavity rubber application, Virtual Molding Technology, available through Sigmasoft®, reduced in 47% the runner volume and in 30s the cycle time.

The design of molds for rubber processing has always been linked to a great deal of trial-and-error. Features such as tempering and runner layout, as well as material selection are done based rather on guessing or experience than on knowledge, and the processing parameters are not set until the mold has been completely built. Often the mold has to be reworked and operates far from its optimum, wasting energy and raw material.

Sigmasoft®, through its Virtual Molding Technology, changes this fundamentally, as it allows simulating the complete mold over several molding cycles, with all detail about molded material and mold components. Virtual Molding has been conceived to support the part and mold design, as well as the processing set-up, in such a way that all iteration can be done virtually, without material or machine-time waste, while understanding the causals for process problems and identifying potential for improvement.

The company Aspem Ferramentaria, Brasil, used Virtual Molding to optimize a 48 cavity mold, with forming dimensions of 700 x 550 mm2. The objective was to analyze the tempering concept and to evaluate possibilities for raw material savings.

At first, the thermal behavior of the mold was considered. The complete mold design, with all parts and tempering elements, was introduced in Sigmasoft® and run virtually, just as in the injection molding machine, for several cycles.

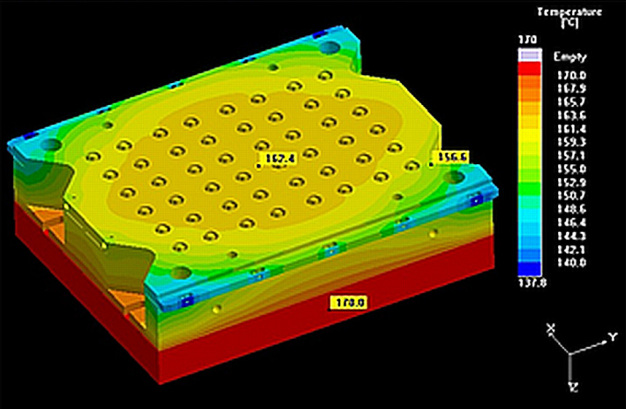

The effectiveness of the tempering layout can be seen in the temperature distribution of Figure 1. In this case, the temperature distribution is presented after 340s of cycle time. From the thermal analysis it was evident that the cavities of all four corners of the mold had a lower mean temperature than the rest of the parts. The pieces molded in the center of the cavity would achieve 90% average curing degree within 310s, while the parts located at the four corners had only 75% of average curing degree at the same time. They would need 30 longer to achieve 90% of average curing degree. Therefore, it was decided to eliminate those four cavities, to avoid material waste, and it was possible to reduce the cycle time from 340s to 310s.

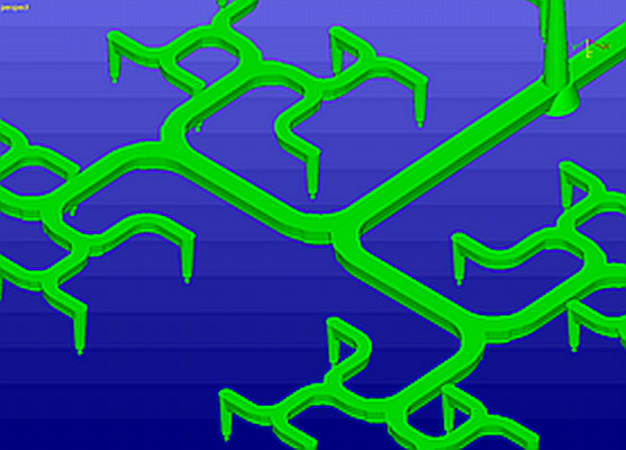

A second objective was to reduce the amount of raw material. In this case a cold runner was used, and the possibility of reducing the runner diameter was evaluated. When considering a size reduction in the runner system, it is important to consider different factors: a very small cross section increases the shearing stress and may lead to material degradation in the cavity. Also the scorch in the runner must be considered, as a higher proportion of surface-to-volume reduces the required curing time in the runner. Additionally, the pressure demand must be considered.

Several simulations with Sigmasoft®, evaluating the parameters of critical shearing, scorch and pressure demand, leaded to a reduction of 47% in the runner volume, from 159 cm3 to 75 cm3, as seen in Figure 2. The raw material consumption was reduced in 89g per shot. With a total cycle of 360s over 24 h, and the cost of raw material based at 4,95 EUR per kg, the savings over a year added to 25,587 EUR.

“Experience demonstrates how the project and process can be analyzed beforehand. When combining technical experience and simulation, it is possible to attain a high profit margin”, commented Luciana Stewe, the Sigmasoft® engineer in Brazil who supported the project. “The whole project, from the thermal analysis of the mold, the dimensioning of the runner, the selection of the cavity numbers and the reduction in the volume channel was completed in 4 days”, she commented.

SIGMA Engineering GmbH

52072 Aachen

Germany