Automotive Molding: First Shot Success with Virtual Molding

Sigmasoft® shows how to achieve first shot success for automotive applications with narrow tolerances at Swiss Plastics 2014

Usually the search for an optimal process window for parts with narrow tolerances is very time consuming. With the help of Sigmasoft® Virtual Molding, the mold and process can be optimized without wasting valuable resources. Kalypso Ultra Technologies helped their customer achieve first shot success for a high precision automotive product using this Virtual Molding technology.

At Swiss Plastics 2014 Sigma Engineering GmbH presents how Sigmasoft® Virtual Molding helps optimize the mold and process, before the mold is built.

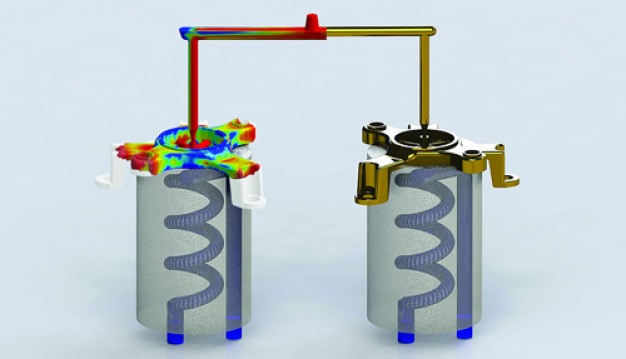

Charged with the development of a structural mount (Picture 1) out of PA 6.6 with 30% glass fibers, a diameter of 10 cm and tolerances of +0,07 mm /-0,0 mm for every cross section, several challenges existed for Kalypso. The material behavior is very complex due to crystallization and fiber orientation and is difficult to predict so common design rules do not apply. The part geometry is unusually complex with large differences in wall thickness and narrow tolerances where only little experience could be gathered from past learning. Optimal gating and reliable tempering are a prerequisite for success on these kinds of products. Contrary to the usual trial-and-error approach, which is very time consuming and expensive, Kalypso consequently decided to develop the mold and process virtually with Sigmasoft® before building the mold.

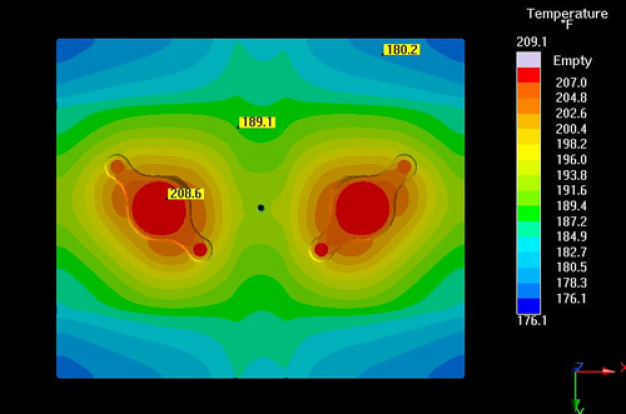

A multi-cycle analysis consisting of 20 consecutive virtual production cycles using actual process parameters and conventional cooling revealed hot spots on the mold cores (Picture 2a) during the steady production state of the mold. Hot spots are difficult to manage in a production mold and they influence part distortion because they create variations in crystallization, resulting in non-uniform shrinkage and distortion. Reducing water temperature typically only makes the cold areas colder and increasing cooling time is expensive so these common strategies don’t always work. As an alternative, a potential solution using conformal cooling in the mold cores was discussed and then evaluated, virtually. In this case, the consideration of all mold components and process parameters over several cycles showed a more regular temperature distribution inside the mold (Picture 2b) as well as a reduction in cycle time.

Based on this new information, the mold was built and the process parameters were predetermined. The production staff was specifically prepared for the required process in advance to avoid wasting time during the physical trials at the molding machine. The new mold and process produced the required part quality from the start. Kalypso was able to deliver the mold and process to their customer on schedule and still achieve success during the first molding trial. Sigmasoft® Virtual Molding helped them achieve a first shot success without time consuming mold and process iterations.

SIGMA Engineering GmbH

52072 Aachen

Germany