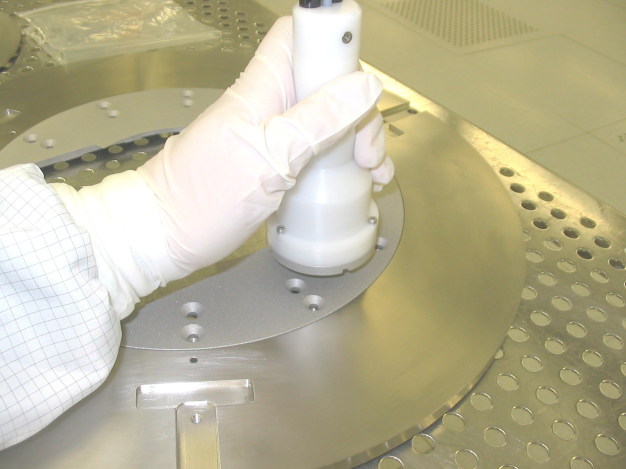

LASER PARTICLE COUNTER ASPC 10/250

Today the quality of products manufactured in pure areas and their

continuing safety device in crucial measure of an effective

quality/process monitoring depends. CCI immediately logging,

evaluation of surface particles in a particle spectrum between 10 to

250 offers µm an interesting addition at the particle counter market

to ASPC 10/250 with the laser particle counter for the measurement.

Primary operational areas: 1) surface particle measurement with

substrate surfaces (z. B.Automotives industry, micro mechanics, printed circuit board

production, Pharmaindustrie) 2) process quality monitoring 3)

monitoring quality/effectiveness of pure space cleaning equipment

specification: - measuring particle sizes between 10 to 250 µm in a

gradation of up to 0,1 µm  selectable - measurement in almost any

environment (outside air to RR class ISO 6) - 16Â f r e iÂ

configurable channels - 99 designate-cash/markable measuring points

per measuring program - data memory of more than 150 measurements per

everyone that entirely 16 measuring programs  (max.: 2,400

measurements) - regulated air flow of 28,3 l/min. - measuring and

interpretative programs under Win 98, 2000, XP - data export in the

measuring and evaluation software into own Excelvorlagen -

generation/storage of the measuring programs directly am  particle

counters or of the PC - limit value definition for each counter

channel - during excess printer expression  and/or.acoustic alarm clay/tone - serial interface for communication with a

PC - mains connection detailed info. for this?