Bionic bio-fan from Ziehl-Abegg: Better in every way

• Significant CO2 saving in the manufacture

• Low noise development

• Reduced electricity consumption during operation

• Better load capacity, temperature resistance, long-term stability and mechanical properties

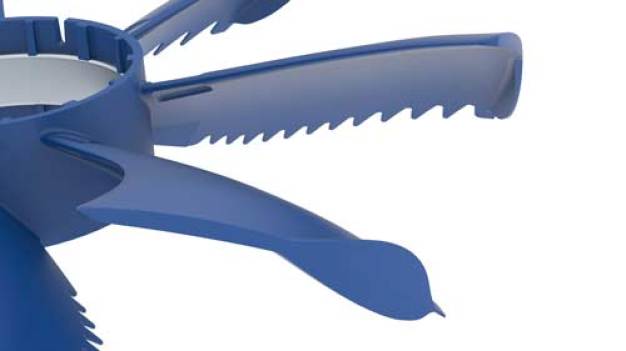

“We can save the environment thousands of tonnes of CO2 every year with these fans,” says Managing Director Peter Fenkl. His company, Ziehl-Abegg (Kuenzelsau), now presents a bionic bio-fan. The new fan consists of castor oil-based bio-polyamides. In addition to the CO2 saving, there are improvements in the load capacity, temperature resistance and long-term stability as well as the mechanical properties. Since the blade geometry incorporates knowledge from bionics, the fan is also quieter and more efficient – and therefore reduces electricity costs and noise emissions in operation.

This revolutionary design is used, for example, in refrigeration engineering (refrigeration chain for food to the supermarket), in heaters, heating pumps and for electrical cooling (computer centres, control cabinet cooling, inverter cooling). In keeping with its sustainable concept, the fan is 100 percent recyclable. Although the CO2-footprint is considerably minimised, it has benefits for appliance planners: The fan has greater chemical resistance and better low-temperature impact strength and withstands hot water and steam.

20 years ago "fair" coffee was just for bohemian types. Now more and more people are looking beyond the advertising claims at shipping distances and manufacturing processes. The bionic bio fan is similarly a pioneer in this sense even if the price is currently higher than for petroleum-based products. With equivalent performance data and dimensions to conventional fans there are no technical barriers. However the market needs attuning to this product and its positive environmental features.

In technical terms the bionic bio fan offers several benefits in addition to its environmental contribution: Unlike petroleum-based products it has very low water absorption and a considerably longer lifespan as well as better chemical resistance. “Ziehl-Abegg as a trendsetter in fan development therefore also wants to be a pioneer in the use of bio-polymers,” says Managing Director Fenkl.

1. Bionics (less noise and less energy use)

The designers of Ziehl-Abegg have been observing many creatures whose bodies are optimised for water or air flow. The engineers were struck by the quietest of the birds of prey - the owl.

Just why is the owl so quiet? The owl hunts at night when visibility is very poor. Owls therefore locate their prey by hearing. And this only works if they can fly extremely quietly. How do they do that? A barn owl for instance weighs around the same as a pigeon. Their wings however are several times larger and more arched. This gives the bird much more uplift at lower speeds. Pigeons on the other hand have to flap their wings hard which makes them audible from afar.

The tips of the owl's wings are also fringed. This causes the air flowing over and underneath the wings to meet at the rear edge of the wings more gently and therefore more quietly. The rear edge of the fan blade is serrated for the same reason.

However the company's designers did not just scrutinise owls. Vultures, eagles and storks raise individual feathers. These create small border-vortices at their tips, further reducing the resistance of the wing. You can also see this in aeroplanes whose wings now have a small nick (or winglet) at their tip. Ziehl-Abegg owlet fan-blades have long had this feature.

The combination of several bionic features in a single fan also reduces the energy consumption in operation.

2. Biomaterial in the fan (CO2-reduction during manufacture)

Sustainable raw materials in place of fossil fuels contribute to a reduction of CO2 emissions. 60% of the fan blade is composed of the sustainable raw material sebacic acid which is obtained from the oil of the castor oil plant.

Castor oil (CAS-no. M8001-79-4) is a plant oil which is obtained from the seeds of the tropical castor oil plant (Ricinus communis), which belongs to the Spurge family. It is a triglyceride with pharmaceutical names Oleum Ricini s. Castoris, Ricini oleum virginale and castor oil (castor oil in English-speaking countries, but also ricinus oil or oil of Palma Christi).

In moderate climates the plant grows as an annual but it is a perennial in the tropics. The plant is fast-growing and under ideal conditions it can reach 5 m within three or four months. In tropical climates after several years it can reach heights of up to 30 m and forms a woody stem. In temperate climates the plant dies down each year and then re-shoots when there is sufficient sunlight.

The castor oil plant also grows in a semi-arid climate (from the Latin aridus = dry, arid) and is therefore drought resistant. The most important producing country for castor oil is India. With an annual 750,000 tonnes it represents around 60 percent of the world production. Further important producing countries are the People's Republic of China and Brazil.

Castor oil is obtained from cultivation on low nutrient soils which are too poor for other crops so that it is not in competition with food production. The castor oil plant and/or the castor oil is not a food product.

It is possible to process biopolyamides like conventional plastics on conventional machines simply by adjusting the process parameters.

Since the castor oil tree absorbs CO2 in the growth phase, it reduces the CO2 emissions by two thirds as compared to petroleum-based plastics. It is therefore a drastic CO2 saving. Managing Director Peter Fenkl: "The use of plant-based raw materials which have already extracted CO2 from the environment in the growth phase means that the CO2-balance sheet of the material overall is significantly better as compared to polymers based on fossil fuels." The whole fan blade (including 30 percent fibreglass/GF 30) still represents a CO2 saving of 40 percent.

Since the material contains more than 60 percent sustainable raw material, it meets the current definition of a bio-plastic.

So-called biopolymers are counted into the Lead Market Initiatives of the European commission when the following preconditions are fulfilled: a sufficient level of industrial production and no competition with food production. Both these facts apply to castor oil-based biopolymers.

3. Bio-material reduces the weight of the fan

The bio-fan is 6% lighter in comparison with products made of PA6 GF30 (fossil-based). This results firstly from a 5-percent reduction in density and secondly from a far lower moisture absorption (PA 6 GF 30: density 1.36 and moisture absorption 2.1-2.3 % compared to biomaterial GF30: density 1.31 and moisture absorption 1.2 %.).

4. Bio-material has a number of positive characteristics

For the customer this new material offers many benefits, i.e. even more possibilities for use of this fan.

• Greater chemical resistance (stress fracture-resistant under the influence of aggressive chemicals)

• Hot water- and steam resistant (high hydrolysis resistance)

• Absorbs 50% less moisture

• Dimensionally stable

• Better low-temperature impact strength

• Good abrasion/wear behaviour

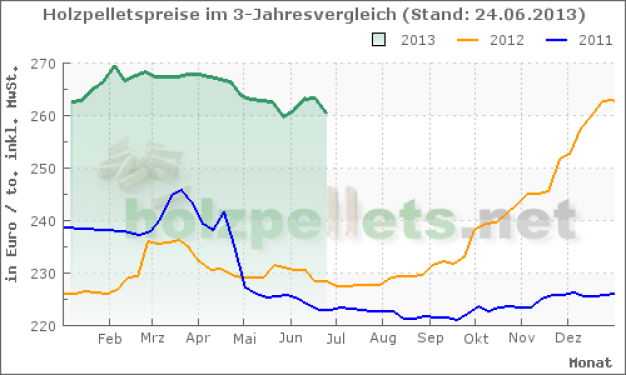

5. Wood is not a suitable substitute for fossil fuels

The use of wood as a substitute material is not an option for Ziehl-Abegg since this has a direct financial impact on owners of houses and flats who use wood or pellets for heating. (see table 1)

Lead Market Initiatives of the EU

The European Commission launched the Lead Market Initiatives (LMI) in 2007 and selected bio-based products as one of six target markets. The LMIs employ demand-orientated measures aimed at significantly increasing the potential and competitiveness of bio-based products.

Un-economical: The major obstacle for experts when questioned is the continued higher costs for bio-based products as compared to product alternatives so that the development of bio-technological production processes is generally un-economical.

Background:

Bio-based products have considerable potential for the reduction of production-related environmental impact, for improved health, as a sustainable alternative to fossil fuel-based raw materials and to ensure the international competitiveness of German and European industry through technology leadership. This potential however cannot be fully exploited at this point. Various obstacles stand in the way, e.g. absence of cost competitiveness to some extent, low acceptance in the processing industry, "time to market" dominance, biased regulations, relative favouring of energy- compared to material utilisation of biomasses. Tailoring support is made difficult because of the extreme heterogeneity of the products and the variety of potential application fields (including bio-chemicals, bio-lubricants and bio-plastics for packaging as well as for construction or the automotive industry).

High-tech-strategy of the German Government (2006)

The high-tech-strategy of the German Government is aimed at placing Germany at the forefront of the most important markets of the future. The plant as a supplier of raw material is one of 17 future-fields in which innovation strategies have been defined. In this context, by 2015 Germany aims to achieve pole position in Europe in plant biotechnology and plant engineering and to considerably expand the use of renewable and sustainable raw materials in the chemical industry.

Ziehl-Abegg SE

74653 Künzelsau

Germany