Tack-free production of one-way syringes

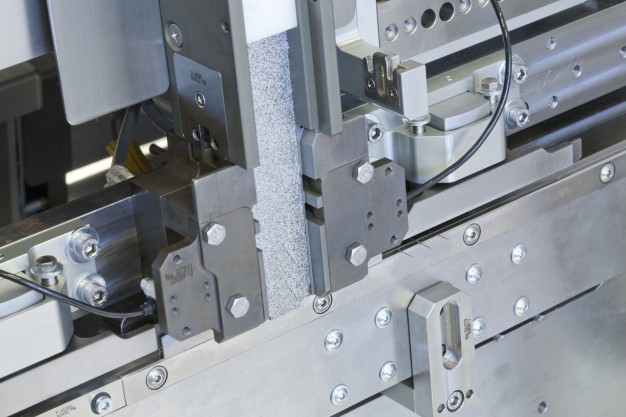

ZAHORANSKY Stuttgart shows a tack-free, fully automatic production plant for one-way syringes in co-operation with the companies angel, A-4311 sword mountain and Transcoject, D-24539 new Muenster, to the Medtec. Around this to make possible ZAHROANSKY an high-efficient needle sort system (NFS) with up to 400 needles per minute developed to be isolated. The isolated needles arrive over one in the own house developed servo-motor propelled linear robots into the spraying casting tool. Optionally the needle syringes can be also aligned before. In the tool the inserted needles are usually umspritzt directly with a high-quality plastic, a technical polymer, COC (Cyclo Olefin copolymer). Tack-free manufacturing of Kan�len is absolutely new, because well over 95% all Kan�len are today still adhesive - usually in wage labour abroad. The process steps in detail: The NFS plant isolates in each case 16 needles by means of a slidegate valve of the Zuf�hrungsmagazin. Subsequently, the fourwheel linear robot hands the needles over, which already suitably the tool in corroding accurately positioned on a receiving plate are, into the ejector-lateral tool cavities. During the insertion phase over a 6-Achs-Gelenkroboter Engel the finished squirted parts on the nozzle-lateral tool half is taken from the company at the same time. This reduces the cycle time considerably, since supply and withdrawal take place parallel. The glass-similar COC polymer is injected over a Ewikon hot duct system with needle catch nozzles. The cavity employments are heated under the plastic material, while the remaining tool is normally cooled. In addition the employments were separated thermally from the tool, in order to minimize losses of energy and to receive fast a thermal equilibrium of the plant. Laser apparatuses examine on the one hand the supply of the needles and on the other hand the umspritzten needles for completeness. The finished syringe bodies can be silikonisiert afterwards in an integrated subsequent station, in order to obtain a better gliding ability of the needles. Subsequently, the automatic packing takes place. Like that it is ensured that during the complete process chain no particle contamination can take place via hands. The automated manufacturing is on the Medtec in Stuttgart on the angel conditions 4415 in resounds to 4 on angel an emotion 200-100T injection moulding machine in pure space execution in function to see

This text was translated automatically.

ZAHORANSKY Formenbau GmbH

79108 Freiburg

Germany