ANGEL with large success on the Fakuma

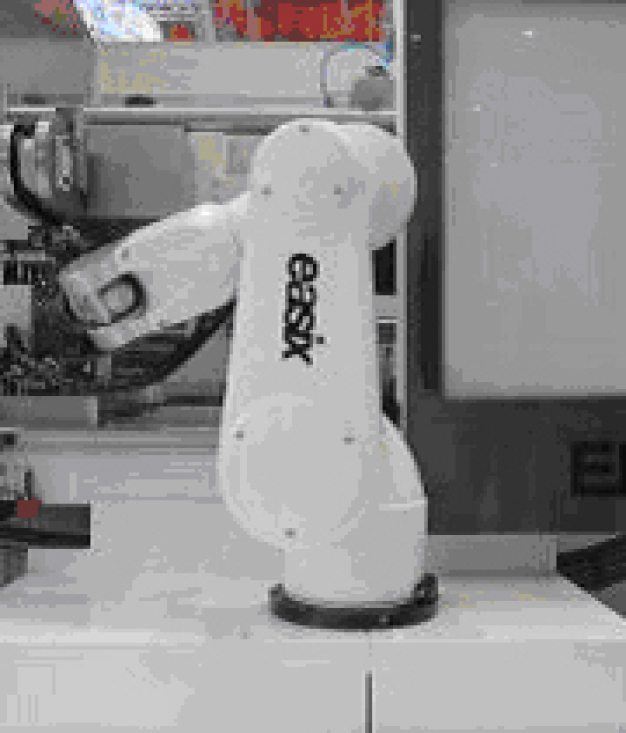

Continuous a well visited exhibition booth, exciting project inquiries and numerous sales conclusions: For ANGEL AUSTRIA the Fakuma was 2011 a full success. Clear emphasis of the system offerer in Friedrichshafen: Automation. Five highly integrated manufacturing cells demonstrated at the exhibition booth, how can spraying pouring hurry in highest quality be produced with custom-made solutions in the most different user industries efficiently and economically. � the Fakuma develops to one the Top Kunststoffmessen world-wide �, stresses Gerd Liebig, Group marketing director from ANGEL AUSTRIA after conclusion of the fair week at the end of of Octobers in Friedrichshafen. � the thematic focus of the exhibitors is directed ever more strongly toward innovations. That is it, which makes the fair visit for the plastic processing plants be worth worth. � equivalent two topics at the angel exhibition booth proved as true public magnets: the Sensitive Surface technology, which points the way to the automobile developers into the future of the smarten cockpit, and easix, the complete integration of multi-oh robots into the controlling of the angel injection moulding machines. Sensitive Surface: First applications of series in few years that cars in the future still more comfortably than Smartphones by simply affecting, feeling and interaction be served can, of it could themselves the visitors in the cockpit simulation at the exhibition booth of ANGEL convince. In the cockpit of the future capacitive electronics replaces buttons and switches. � this trend open not only the interior designers new degrees of freedom, but makes the production of functional elements also more economically �, thus for Franz F�reder, director/conductor of the ANGELS Business unit of automotives. � we are with different OEMs and car companies in the discussion, in four to five years the first vehicles with this technology will be equipped. � center consoles with sensitiver surface were manufactured at the angel exhibition booth on ANGELS a duo 350 injection moulding machine with turret plate and combination tool in floor technology. But first a capacitive touchskin foil was behind-squirted and afterwards the construction unit surface in the ANGEL clearmelt procedure with PU was flooded. Two linear robots of the type ANGEL viper 20 and ANGEL viper 40 took over the component and partial handling. So the functional devices ready to be installed in a work procedure could be manufactured high-automated. The ANGEL to viper robots was on the exhibition booth of ANGEL besides own exhibition areas dedicated. Because to the Fakuma the starting signal for the new size ANGEL viper 90 fell. Immediately are available the viper robots, which score with maximum stability and highest dynamics, with nominal load abilities from 6 to 90 kilograms. Easy with easix: Operation of fully integrated multi-oh robot with equivalent two exhibits � the production of Nadelhaltern for Insulinpens and of sensor housings for control electronics � demonstrated ANGELS during the Fakuma that Mehrachs industrial robots with the used simple instructions of press control can be served. Under the name easix ANGEL integrates multi-oh robots without euro map 67-Schnittstelle completely into the CC 200-Steuerung of the injection moulding machines. Thus the angel solution differs from many other offerers, who reflect the control surface of the robot for the integration of Mehrachs industrial robots only on the monitor of the injection moulding machine, it the user however does not save to train itself in two different control philosophies. A highest goal of the angel product developers against it reads: Who can serve the injection moulding machine, can also the robot serve. � for the CC 200-Steuerung of the injection moulding machines it does not make a difference longer whether the machine with linear equipment or a Mehrachs industrial robot works, clarifies � J�rg wagoner, managing director of ANGEL automatic control engineering Germany and leader automation of system with ANGEL AUSTRIA. � the control concept is identical for both robot types. � apart from the simple operation and programming the common data storage of machine and robot is a further advantage of the complete control integration, which the efficiency does not only increase, but provides at the same time for a higher measure of process security. Effizienzpotenziale with system approaches optimally exhaustion angels developed consistently of injection moulding machine farmer to the system offerer. � only if all equipment components interlink, leave themselves perfectly Effizienzpotenziale optimally to exhaust. Thus the portion of system approaches, which ANGEL inclusive automation supplies, takes continuously too �, says wagoner. In the meantime nearly each second automated manufacturing cell, which by a European injection moulding machine farmer is sold, of ANGEL, just like each fourth robot supplied to Europe to the spraying casting industry comes. Thus ANGEL is clearly prominent in the automation of injection moulding machines, which reflected itself clearly in the exhibits on the Fakuma 2011. Not only the specific requirements of the individual user industries stand in the focus of the research and development, but also the different land markets with ANGEL. � that the Fakuma gains Gerd Liebig internationally ever more strongly significance, felt we in this year with us at the exhibition booth particularly clearly �, says. � many of our customers take on a far journey, in order to inform in Friedrichshafen about the innovations of the spraying casting technology. �

This text was translated automatically.

ENGEL AUSTRIA GmbH

4311 Schwertberg

Austria