Energieeffizienz und Sicherheit

Definierte Überdrücke gewährleisten die Produkt- und Prozesssicherheit in Reinräumen. Ergänzt man die dafür notwendige Druckmessung durch einen Strömungssensor, wie etwa den SS 20.400 von SCHMIDT Technology, kann durch kontrollierte Luftmengenanpassung die Energieeffizienz zum Betrieb von Reinräumen erheblich verbessert werden.

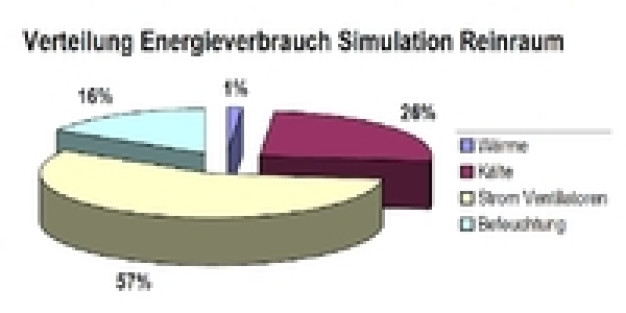

Um Drucküberhöhungen in Reinräumen zu realisieren sind in der Regel recht hohe Volumenströme über die raumlufttechnische Anlage erforderlich. Nicht zuletzt aus Sicherheitsgründen und auf Grund der mit Differenzdrucksensoren sicher messbaren Drücke, schreibt schon die Norm EN ISO 14644 Drucküberhöhungen im Bereich zwischen 5 bis 20 Pascal vor. In beispielsweise pharmazeutischen Reinräumen liegen diese oft sogar zwischen 15 bis 30 Pascal und mehr. Die dafür benötigten Luftmengen, um den Raumdruck zu regeln, machen einen erheblichen Anteil der Energiebilanz einer raumlufttechnischen Anlage zur Versorgung von Reinräumen aus. Erfahrungen aus der Praxis belegen, dass allein über den Stromverbrauch der Ventilatoren rund 57 % der Energiekosten entstehen. Daraus abgeleitet liegt in der Anpassung der Luftmengen an den Bedarf das größte Energie-Einsparpotential. Um dies zu nutzen, gilt es beispielsweise, den Raumluftüberdruck möglichst nahe an die Minimalanforderungen der Norm herunter zu fahren und mit möglichst wenig Zuluft, sprich Ventilatorleistung der RLT-Anlage, fein geregelt stabil zu halten.

Reserve und zusätzliche Sicherheit

Eine ergänzend zur Druckmessung installierte Strömungsmessung, in einer geeigneten Wandöffnung von ca. 50 mm Durchmesser, bietet hier die Möglichkeit, eine so genannte Überströmung, also die aus dem Reinraum auf Grund des darin vorherrschenden Überdrucks ausströmende Luft, sehr genau zu messen. Messbereiche moderner Strömungssensoren, wie die SS 20.400 von SCHMIDT Technology beginnen bereits bei Strömungsgeschwindigkeiten (WN) von 0,05 m/s. Dies liegt weit unter einem Differenzdruck von 0,01 Pa und damit den Möglichkeiten eines Differenzdrucksensors. Folglich weist ein Strömungssensor, in einer Übersrömungsöffnung in der Wand eines Reinraums, sogar noch bei sehr kleinem Differenzdruck eine Überströmung sicher nach. Darüber hinaus sind SS 20.400 Strömungssensoren von SCHMIDT Technology in der Lage, die Strömungsrichtungen bidirektional zu messen, also auch eine eventuelle Rückströmung zu bestimmen. Basis ist ein Thermopile-(Thermosäule)Sensor, der nach dem Prinzip der thermischen Anemometrie funktioniert. Durch Parallelschaltung zweier Halbleiterelemente und aus der Information welches der Beiden das wärmere ist, lässt sich die Strömungsrichtung zuverlässig identifizieren.

Die thermische Anemometrie, wird auf http://schmidt-technology.testimonialsites.de/... näher beschrieben.

Mit der exakten Detektion minimalster Luftströmungen und deren bidirektionaler Erkennung, sind die Strömungssensoren SS 20.400 prädestiniert für die Anwendung in Reinräumen. In Kombination mit den vorhandenen Differenzdrucksensoren lässt sich die Funktionssicherheit von Reinräumen und darüber hinaus deren Energieeffizienz erheblich verbessern. Eine auf praktischen Erfahrungen beruhende Simulation von AL-KO Therm, einem der größten Hersteller von Komponenten für Lüftungs- und Klimaanlagen, belegt, dass so nahezu eine Halbierung der Energiekosten möglich ist.

Bild: Schon der Strom für die Ventilatoren der RTL-Anlage macht 57 % der Energiekosten im Reinraum aus (Schmidt Technology)

SCHMIDT Technology GmbH

Feldbergstraße 1

78112 St. Georgen / Schwarzwald

Germany

Phone: +49 7724 899198

Fax: +49 7724 899101

email: o.joos@schmidttechnology.de

Internet: http://www.schmidttechnology.de