Self-Latching Thanks to Chamfered Pin

Ganter’s indexing plunger selection is extremely diverse. And yet the standard parts experts from the Black Forest continue to find new functional niches to fill: indexing plungers with chamfered pins.

They are nearly universal elements that can be found anywhere that latching, locking and securing is required: indexing plungers. Despite the diverse range of types and dimensions, they previously all had one thing in common: The latching process typically makes use of a cylindrical hole that is aligned with the plunger pin, allowing the pin to engage without difficulty. For example, when a carriage travels past a latching hole.

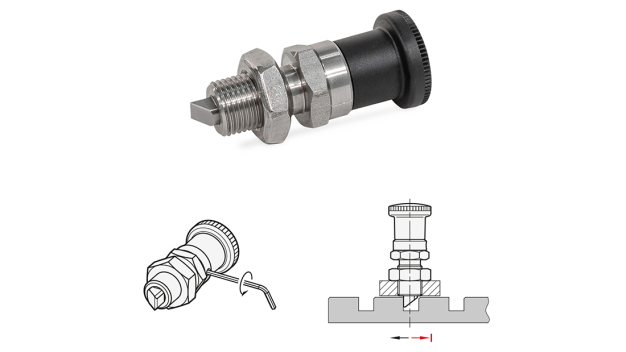

But there are also cases in which only an edge or a groove must suffice for latching, and it may not even be precisely positioned relative to the plunger pin. For such situations, Ganter has now developed a new type of indexing plunger that can independently latch into edges and grooves. This is made possible by a chamfered plunger pin. When the chamfered pin encounters a raised latching geometry, it retracts and then springs back out again once it reaches the latching point.

The new indexing plungers can be ordered under Ganter number GN 824 with axial thread for fastening and a black plastic knob for operating the indexing plunger. To ensure that the latching on approach functions reliably, Ganter makes the plunger pins out of hardened, robust stainless steel with a square cross-section and common dimensions. As always, the developers at Ganter think of everything: When the indexing plunger is screwed in and secured using a standard M12 … M20 thread, the chamfered pin initially sits at an arbitrary angle. To ensure that it actually encounters the mating surface perpendicularly, the plunger pin can be adjusted by 360 degrees – simply by loosening a grub screw in the base ring. A marking on the ring shows the orientation of the chamfered pin – even when the plunger pin itself is not visible.

If the indexing plunger needs to be temporarily disabled to prevent automatic latching, the types C and CK with rest position can be used. When the pin is retracted and the knob is turned by 90°, a retaining groove keeps the knob held in this position. Versions that include a lock nut allow for individual adjustment of the latching depth by positioning the lock nut on the mounting thread.

Indexing plungers with chamfered pin are particularly well suited for applications in which transport frames, mechanisms or covers need to be quickly and securely locked in place, especially without the need for manual intervention.

That’s why GN 824 is not the only version available. The family with the designation GN 724 offers the identical basic functionality but with different shapes and mounting options. In addition to simple indexing plungers that feature an operating ring and can be screwed or welded in place, this product family also includes indexing plungers with spring latches of steel or stainless steel. As it travels along the curved edge of the housing, the latch arm produces an axial displacement so that the plunger pin is retracted and remains retracted until the latch arm is rotated back out of the retaining groove at the end of the curve.

![]()

Otto Ganter GmbH & Co. KG

Triberger Straße 3

78120 Furtwangen

Germany

Phone: +49 7723 65070

Fax: +49 7723 4659

email: info@ganternorm.com

Internet: http://www.ganternorm.com