- Packaging, Foil

Next-level efficiency and sustainability

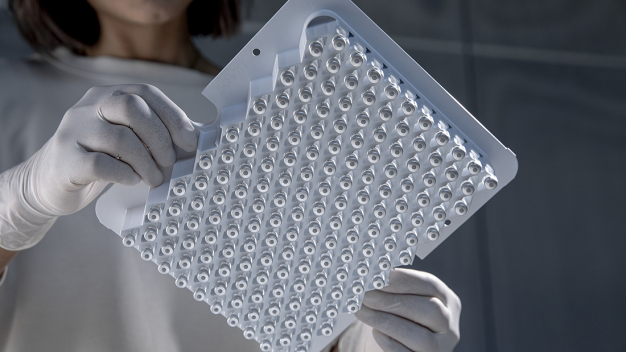

SCHOTT Pharma unveils innovative nest design for ready-to-use cartridges

– New diamond-shaped nest design for ready-to-use (RTU) cartridges boosts efficiency in pharmaceutical filling processes by up to 67% and significantly reduces CO2 emissions by close to 25% in the supply chain for 1.5 ml RTU cartridges.

– Depending on the specifications of the cartridges, the new nest increases packing density by up to 60% while improving stability and maintaining the same external nest dimensions.

– With the new nest, pharma companies benefit from faster fill-and-finish operations of critical medications, including GLP-1, insulin, and hormone therapies.

SCHOTT Pharma, a pioneer in drug containment and delivery solutions, announces the launch of its groundbreaking nest design for ready-to-use (RTU) cartridges known as cartriQ®. The new nest retains its external dimensions, while the cartridges are fixated in diamond-shaped holes instead of round ones. This optimized configuration significantly increases the packing density by up to 60% while improving stability, which is crucial as the cartridges remain in the nest during the entire filling process. “With this revolutionary product, we are proactively addressing one of the key factors in reducing costs for pharmaceutical companies and reorganizing their value chain. Our new nest for RTU cartridges not only enhances operational efficiency by up to 67% when using 1.5 ml cartridges, but also significantly contributes to sustainability efforts in the industry," said Andreas Reisse, CEO of SCHOTT Pharma. "We have received positive feedback from our customers so far," he adds, citing the case of a Big Pharma company where the new nest for 3 ml RTU cartridges has also been optimized for high packaging density using the same approach. In the long term, this change can save a pharma company a considerable amount of CO2 per year.

SCHOTT Pharma’s new nest is available For Human Use (FHU) and is manufactured at the company’s production site in St. Gallen, Switzerland with the outlook of further sites adopting it in the future. It is a complete solution that enhances the efficient filling of high-quality drugs, such as GLP-1, insulin, and hormone therapies. Depending on the requirements of the drug and therefore the format of the cartridge, SCHOTT Pharma managed to fit as many as 160 RTU cartridges in one nest when using the 1.5 ml cartriQ® format while ensuring highest quality and stability.

Driving high-value solutions to meet customer needs

The complete platform of cartriQ® sterile cartridges ranges from small to large filling volumes of 1.5 ml to 20 ml. As an RTU solution, the cartridges are crimped, pre-washed, depyrogenated, siliconized, and steam sterilized. This preparation enables CDMOs and pharma companies to commence the filling process immediately, bypassing the need to manage these preliminary steps themselves. As part of SCHOTT Pharma’s high-value solutions (HVS) portfolio, these cartridges and the new nest exemplify the company’s commitment as a reliable partner to the pharma industry, providing premium, innovative solutions that meet the customers’ needs.

SCHOTT Pharma AG & Co. KGaA

55122 Mainz

Germany